Compressed air systems are essential across industries—from manufacturing and automotive to electronics and pharmaceuticals. However, untreated compressed air contains moisture, oil vapor, and contaminants that can damage equipment, reduce product quality, and increase maintenance costs. For applications requiring extremely dry air, adsorption (desiccant) air dryers are the preferred solution.

Among these, heated regeneration adsorption air dryers offer enhanced efficiency, lower energy consumption, and reliable performance in demanding environments.

This guide provides an in-depth overview of how heated regeneration adsorption dryers work, their various types, advantages, limitations, and key factors to consider when selecting the right unit for your system.

What Is a Heated Regeneration Adsorption Air Dryer?

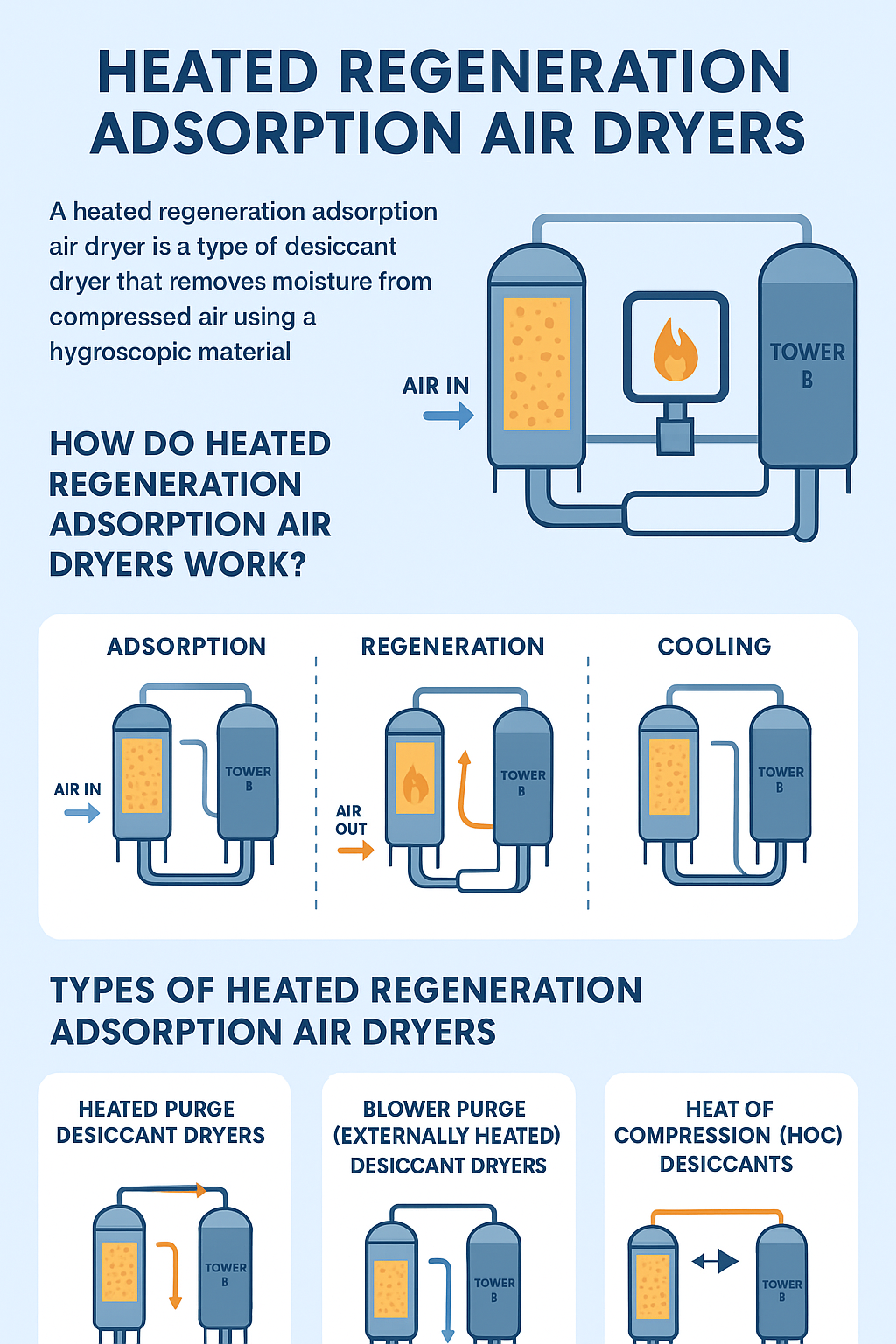

A heated regeneration adsorption air dryer is a type of desiccant dryer that removes moisture from compressed air using a hygroscopic material (such as activated alumina, silica gel, or molecular sieves). Unlike heatless dryers, heated regeneration models use external or internal heating to regenerate (dry) the desiccant, reducing the amount of purge air required and improving energy efficiency.

These dryers usually consist of two towers filled with desiccant. One tower dries incoming compressed air while the other regenerates. The towers alternate to provide continuous dry air.

Heated regeneration dryers are typically used where very low dew points are required, such as:

Instrumentation and control air

Pharmaceutical and food processing

Electronics and semiconductor fabrication

Chemical and petrochemical plants

Powder coating operations

How Do Heated Regeneration Adsorption Air Dryers Work?

While designs differ, the core process includes three main phases:

1. Adsorption (Drying Phase)

Moist compressed air enters Tower A.

Water vapor is captured by the desiccant material.

Dry air exits the system with dew points as low as –40°C to –70°C (–40°F to –94°F).

2. Regeneration (Desorption Phase)

Tower B undergoes regeneration while Tower A dries the air.

Heating is used to release moisture from the desiccant. Depending on design, the heat may come from:

Internal heaters

External heaters

Blower air

Combination heat/purge methods

The applied heat drives out the moisture absorbed in the previous cycle.

3. Cooling

After heating, the desiccant must cool to a stable temperature to avoid increasing the air temperature and dew point when the tower switches back online.

Finally, the towers alternate positions, ensuring continuous air drying.

Types of Heated Regeneration Adsorption Air Dryers

There are three primary types, each with its own operating method and energy profile.

1. Heated Purge Desiccant Dryers

These units use internal heaters to warm a portion of already-dried compressed air (purge air).

Key characteristics:

Uses heated purge air for regeneration

Lower energy cost than heatless dryers

Still consumes some compressed air

Suitable for most industrial applications

2. Blower Purge (Externally Heated) Desiccant Dryers

Instead of using compressed air for regeneration, these dryers use:

An external heater

An ambient air blower

Advantages:

Minimal compressed air loss

Highly energy efficient

Best for large-scale operations and high flow rates

3. Heat of Compression (HOC) Desiccant Dryers

These systems utilize the natural heat generated by oil-free compressors (centrifugal or rotary).

Key advantages:

Extremely energy efficient

No heater required

Very low operating cost

Consideration: Compatible mainly with oil-free compressors.

Advantages of Heated Regeneration Adsorption Air Dryers

Heated regeneration dryers provide several performance and economic benefits:

✔ Very Low Dew Points

Achieve dew points from –40°C to –70°C, ideal for sensitive or precision applications.

✔ Reduced Purge Air Consumption

Heated regeneration cuts purge air use drastically compared to heatless dryers—especially with blower purge and HOC models.

✔ Energy Efficiency

Using external heaters or heat of compression can significantly reduce operational costs.

✔ Long Desiccant Life

Gentler regeneration temperatures prevent dehydrating or damaging the desiccant beads, extending service life.

✔ Stable Performance in Harsh Conditions

Maintain drying capacity in:

Cold climates

High humidity

Variable compressor loads

✔ Suitable for Large Airflows

Industrial production facilities benefit from their scalable design.

Disadvantages and Limitations

✖ Higher Initial Investment

More complex systems mean higher upfront costs.

✖ Requires Electrical Power for Heating

Energy demands vary depending on the dryer type.

✖ Longer Regeneration Cycles

Heated regeneration takes more time compared to heatless models.

✖ Additional Components to Maintain

Heaters, blowers, and sensors require periodic servicing.

✖ Heat of Compression Systems Require Oil-Free Compressors

Compatibility limitation for some factories.

Key Factors to Consider When Selecting a Heated Regeneration Adsorption Air Dryer

1. Dew Point Requirements

Determine whether your application needs:

–40°C

–70°C

Or custom ultra-dry conditions

2. Airflow Capacity

Match the dryer capacity (CFM/m³/min) to your compressor output while accounting for:

Temperature

Pressure

Relative humidity

3. Energy Consumption

Compare long-term operating costs for:

Heated purge

Blower purge

HOC dryers

Even with a higher upfront cost, blower purge and HOC units often offer lower lifetime cost.

4. Installation Environment

Consider climate conditions, space availability, and air quality.

5. Desiccant Type

Different desiccants offer different adsorption characteristics:

Activated alumina: cost-effective and durable

Molecular sieve: achieves ultra-low dew points

Silica gel: high capacity at moderate dew points

6. Maintenance Requirements

Evaluate:

Filter accessibility

Desiccant replacement intervals

Heater/blower service needs

7. Compatibility with Compressors

Especially important for HOC dryers.

Best Applications for Heated Regeneration Adsorption Dryers

Industries that frequently choose heated regeneration dryers include:

Pharmaceutical manufacturing

Food and beverage production

Electronics & semiconductor precision processes

Chemical and petrochemical plants

Automotive painting and powder coating lines

Instrumentation air in refineries

These industries cannot tolerate even small traces of moisture in their air systems.

Conclusion

Heated regeneration adsorption air dryers are among the most reliable and energy-efficient solutions for producing ultra-dry compressed air. By leveraging heat for regeneration, they significantly reduce purge air consumption and provide exceptional dew point performance.

Whether you need a heated purge, blower purge, or heat of compression system, choosing the right dryer depends on your dew point requirements, compressor setup, operating environment, and long-term energy goals.

With proper selection and maintenance, a heated regeneration adsorption air dryer will enhance the reliability, efficiency, and longevity of your entire compressed air system.