Compressed air systems are vital to a wide range of industries—from pharmaceuticals and food processing to chemical plants, automotive facilities, and electronics manufacturing. While compressed air is an essential utility, it also contains moisture that can damage equipment, corrode pipelines, contaminate products, and disrupt sensitive processes.

To achieve low dew points and ensure clean, dry air, heatless desiccant air dryers are one of the most common and reliable solutions.

This ultimate guide explains how heatless desiccant dryers work, their benefits, limitations, applications, and what to consider when choosing the right system for your operation.

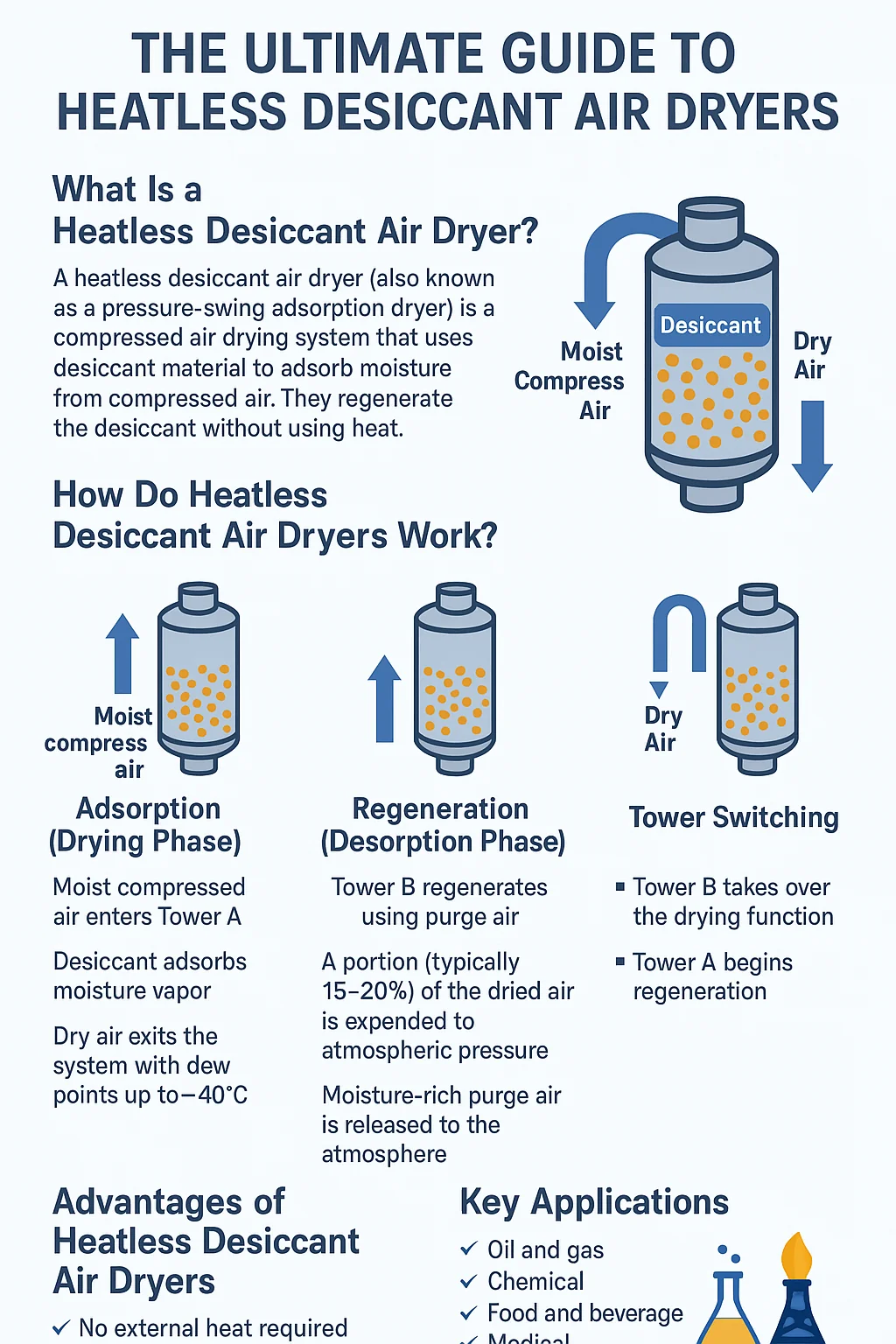

What Is a Heatless Desiccant Air Dryer?

A heatless desiccant air dryer, also known as a pressure-swing adsorption (PSA) dryer, is a compressed air drying system that uses desiccant material—such as activated alumina or molecular sieves—to adsorb (capture) moisture from the air.

What makes heatless dryers unique is that they regenerate the desiccant without using heat, relying purely on pressure changes and a small portion of dried purge air to remove moisture from the saturated desiccant.

Characteristics:

Two desiccant towers (Tower A and Tower B)

Delivers dew points as low as –40°C (standard) or –70°C for ultra-dry requirements

Uses 15–20% purge air for regeneration

No external heaters required

Simple, reliable, and suitable for harsh environments

How Do Heatless Desiccant Air Dryers Work?

Heatless dryers operate on a continuous two-tower adsorption/regeneration cycle.

1. Adsorption (Drying Phase)

Moist compressed air enters Tower A.

The desiccant adsorbs moisture vapor.

Dry air exits the system with dew points up to –40°C or below.

2. Regeneration (Desorption Phase)

Meanwhile, Tower B regenerates using purge air:

A portion (typically 15–20%) of the dried air is expanded to atmospheric pressure.

The low-pressure dry air absorbs moisture from the saturated desiccant.

Moisture-rich purge air is released to the atmosphere.

3. Tower Switching

Once Tower A becomes saturated:

Tower B takes over the drying function.

Tower A begins regeneration.

A controller manages the cycle time, pressure, and switching to maintain continuous dry air supply.

Advantages of Heatless Desiccant Air Dryers

✔ No External Heat Required

Simplifies design and reduces mechanical complexity.

✔ Extremely Reliable and Robust

No heaters, blowers, or complex controls—ideal for:

Remote installations

Cold climates

Harsh or variable environments

✔ Consistent Low Dew Points

Capable of dew points:

–40°C (standard)

–70°C (optional)

Suitable for critical processes like instrumentation and electronics

✔ Easy to Install and Maintain

Few moving parts mean:

Lower maintenance

Simple setup

Minimal downtime

✔ Works Well in Low Ambient Temperatures

No heater elements that struggle in cold conditions.

Disadvantages of Heatless Desiccant Air Dryers

✖ Higher Purge Air Consumption

Consumes 15–20% of dried compressed air for regeneration.

This increases energy costs for systems with high air demand.

✖ Higher Operating Cost Compared to Heated Dryers

Over time, purge-loss can cost more than energy used by heated models.

✖ Sensitive to Oil Contamination

Oil vapors can damage desiccant, requiring filtration and regular maintenance.

✖ Lower Efficiency for Large-Scale Operations

High purge-air losses make them less ideal for high-flow industrial systems.

Key Components of Heatless Desiccant Dryers

Desiccant towers

Activated alumina, silica gel, or molecular sieve desiccant

Inlet and outlet filtration

Check valves and switching valves

Controller / timer

Purge orifice

Diffusers

Moisture indicators or dew point sensors (optional)

Where Are Heatless Desiccant Air Dryers Used?

Heatless dryers excel in environments where reliability, low-temperature operation, or extremely dry air is required.

Common Industries

Oil and gas

Chemical and petrochemical

Food and beverage

Medical and pharmaceutical facilities

Electronics and semiconductor production

Automotive painting and powder coating

Power generation and instrumentation air

Typical Applications

Pneumatic control systems

Air-powered tools in cold environments

Drying air for laboratories or medical devices

Preventing corrosion in pipelines and control valves

Protecting sensitive sensors and actuators

Types of Heatless Desiccant Dryers

While all heatless dryers use PSA and purge air, variations include:

1. Fixed-Cycle PSA Dryers

Run on a standard timer (e.g., 10 min adsorption / 10 min regeneration)

Simple but not optimized for fluctuating moisture loads

2. Dew Point–Demand Controlled Dryers

Adjust cycle based on real-time outlet dew point

Reduce purge air usage

Lower operating cost

3. High-Pressure Heatless Dryers

Designed for pressures up to 350 bar

Used in PET bottle production and specialized industrial applications

4. Explosion-Proof or Hazardous-Area Models

Certified for ATEX or Class I/II environments

Required in oil, gas, and chemical industries

Purging Methods in Heatless Dryers

There are two primary purge strategies:

1. Fixed Purge

A constant percentage (15–20%) of dry air is always used

Simple but wasteful during low-load conditions

2. Variable Purge

Purge air adjusts based on humidity, flow, or dew point

Cuts energy cost significantly

Improves desiccant life

Key Considerations When Choosing a Heatless Desiccant Air Dryer

1. Required Dew Point

–40°C for standard industrial use

–70°C for ultra-dry applications (electronics, pharma, etc.)

2. Purge Air Loss

Factor purge air cost into total operating cost.

3. Flow Rate & System Size

Oversizing leads to unnecessary purge loss; undersizing fails to meet dew point requirements.

4. Desiccant Type

Activated alumina: most common, durable

Silica gel: high adsorption capacity

Molecular sieve: best for ultra-low dew points

5. Filtration

To protect and extend desiccant life:

Pre-filter (oil removal)

Particulate after-filter

6. Ambient Temperature

Heatless dryers excel in cold environments, unlike heated models.

7. Installation & Maintenance

Consider:

Valve accessibility

Tower design

Cycle-time configuration

Availability of service parts

Maintenance Requirements

Heatless dryers require consistent but straightforward maintenance:

Replace desiccant every 3–5 years depending on air quality

Check and service valves and seals

Replace inlet and outlet filters regularly

Inspect purge orifice and check valves

Monitor dew point performance

Maintain clean, oil-free compressed air supply

Good maintenance ensures stable dew points and long equipment life.

Advantages Compared to Heated Regeneration Dryers

| Feature | Heatless Dryer | Heated Dryer |

|---|---|---|

| Regeneration Method | Purge air only | Heater + purge/blower |

| Purge Air Use | Higher | Lower |

| Complexity | Low | Medium–High |

| Best For | Small–medium flow, cold climates | Large flow, energy optimization |

| Initial Cost | Lower | Higher |

| Operating Cost | Higher (purge loss) | Lower (but more maintenance) |

Conclusion

Heatless desiccant air dryers are a proven, reliable solution for achieving low dew points in compressed air systems. They require no external heating, making them simple to install, operate, and maintain—even in harsh or cold environments. Although they consume more purge air and have higher operating costs than heated regeneration dryers, their reliability and simplicity make them highly popular in many industries.

By understanding how they work, their advantages and limitations, and key selection considerations, you can choose the ideal heatless desiccant dryer for your air system—ensuring dependable, clean, and dry air for years to come.