Clean and dry compressed air is essential for ensuring the reliability, efficiency, and longevity of pneumatic equipment. Among the many technologies used for moisture removal, modular heatless desiccant air dryers have become increasingly popular due to their compact design, energy-efficient performance, and exceptional reliability.

This guide explores how these dryers work, their advantages and disadvantages, and the key factors to consider when selecting one for your compressed air system.

What Is a Modular Heatless Desiccant Air Dryer?

A modular heatless desiccant air dryer removes moisture through adsorption using desiccant material such as activated alumina. Unlike heated or blower-heated dryers, heatless dryers regenerate the desiccant using only a small percentage of dry purge air—no external heat source required.

What makes this type modular is its construction:

Multiple small, lightweight modules instead of large vessels

Easily installed, serviced, or expanded

Ideal for tight spaces or OEM integration

Typical performance: dew points of –40°C and even –70°C when required.

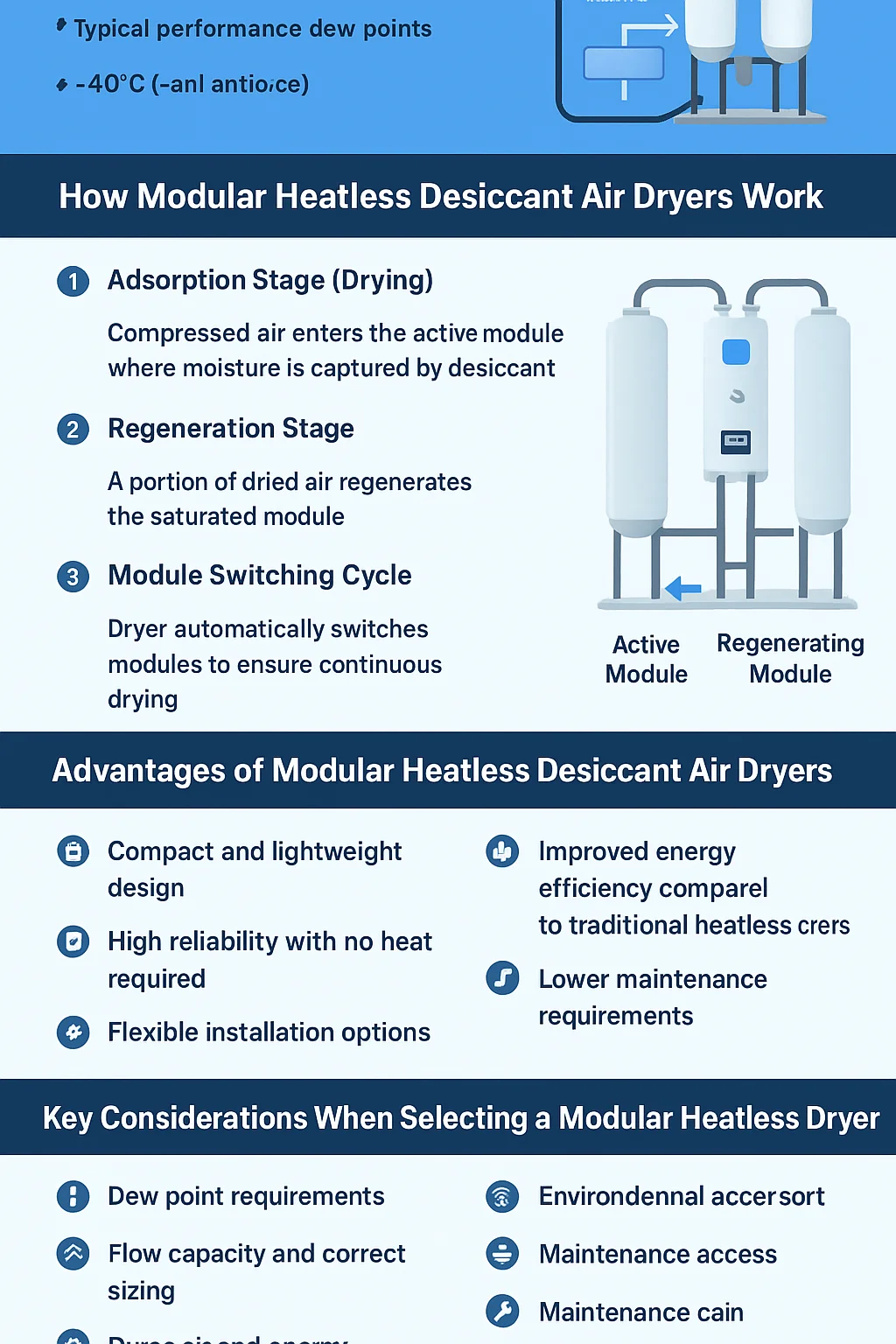

How Modular Heatless Desiccant Air Dryers Work

Adsorption Stage (Drying)

Compressed air passes through the active module where moisture is captured by the desiccant. As the air exits, it is extremely dry and suitable for sensitive downstream applications.

Regeneration Stage

A portion of dried air expands to atmospheric pressure and flows backward through the saturated module, removing moisture from the desiccant.

Module Switching Cycle

Once regeneration completes, the system automatically switches modules, ensuring continuous and uninterrupted drying.

Advantages of Modular Heatless Desiccant Air Dryers

Compact and Lightweight Design

Modular dryers require far less space—up to 70% less—than traditional twin-tower systems. They can be wall-mounted or installed close to the point of use.

High Reliability with No Heat Required

No heaters, blowers, or complex systems mean fewer failure points, ideal for mission-critical environments.

Flexible Installation Options

Modular construction allows vertical/horizontal mounting and easy integration into equipment skids or manufacturing cells.

Consistent Low Dew Points

Stable dew points of –40°C meet ISO 8573-1 Class 2 moisture standards.

Improved Energy Efficiency Compared to Traditional Heatless Dryers

Optimized purge cycles and cartridge-based desiccant beds reduce overall consumption.

Lower Maintenance Requirements

Desiccant cartridges can be changed quickly without special tools, lowering downtime and costs.

Disadvantages of Modular Heatless Desiccant Air Dryers

Purge Air Consumption

Regeneration requires purge air, reducing system efficiency. This is inherent to all heatless dryers.

Not Ideal for Very High Flow Rates

Modular designs excel in small–medium applications; large systems may favor heated technologies to lower operational energy cost.

Higher Long-Term Energy Use Than Heated Regeneration

Since purge air is used instead of heat, energy cost may be higher in large installations.

Sensitive to Inlet Contamination

Oil or particulates can damage the desiccant, making high-quality pre-filtration essential.

Key Considerations When Selecting a Modular Heatless Dryer

Dew Point Requirements

Match the dew point to your application needs:

–40°C for general industrial use

–70°C for medical, electronics, or precision manufacturing

Flow Capacity and Correct Sizing

Consider inlet temperature, pressure, and peak demand conditions when sizing.

Purge Air and Energy Consumption

Typical purge rate: 15–20% of rated flow.

Choose models optimized for minimal purge loss.

Installation Space and Layout

Modular dryers are ideal where space is limited or point-of-use drying is preferred.

Environmental Conditions

Ambient temperature and humidity influence dew point stability.

Maintenance Access

Look for systems with simple desiccant changes, easy filter access, and clear service indicators.

Applications of Modular Heatless Desiccant Air Dryers

These dryers are used broadly in environments requiring reliable, ultra-dry compressed air:

Pharmaceutical production

Laboratories

Medical and dental air systems

Electronics and semiconductor manufacturing

CNC and robotic systems

Food and beverage packaging

Instrumentation and control systems

OEM integrated machinery

Conclusion

Modular heatless desiccant air dryers provide a reliable, compact, and energy-efficient solution for achieving low dew points in compressed air systems. Their modular construction and easy maintenance make them ideal for modern industrial facilities that require flexibility, performance, and minimal downtime.

By understanding how they work and what selection factors matter most, you can choose the right modular dryer to optimize your air system’s performance and reliability.