In any compressed air system, moisture is the enemy. When air is compressed, water vapor becomes concentrated and can cause rust, corrosion, microbial contamination, and equipment failure. That’s why a refrigerant air dryer is one of the most widely used solutions in industrial and commercial compressed-air applications today.

Reliable, efficient, and easy to maintain, refrigerant dryers provide a stable dew point suitable for most manufacturing processes. If you’re trying to understand what they are, how they work, and whether they’re right for your facility, this guide has everything you need.

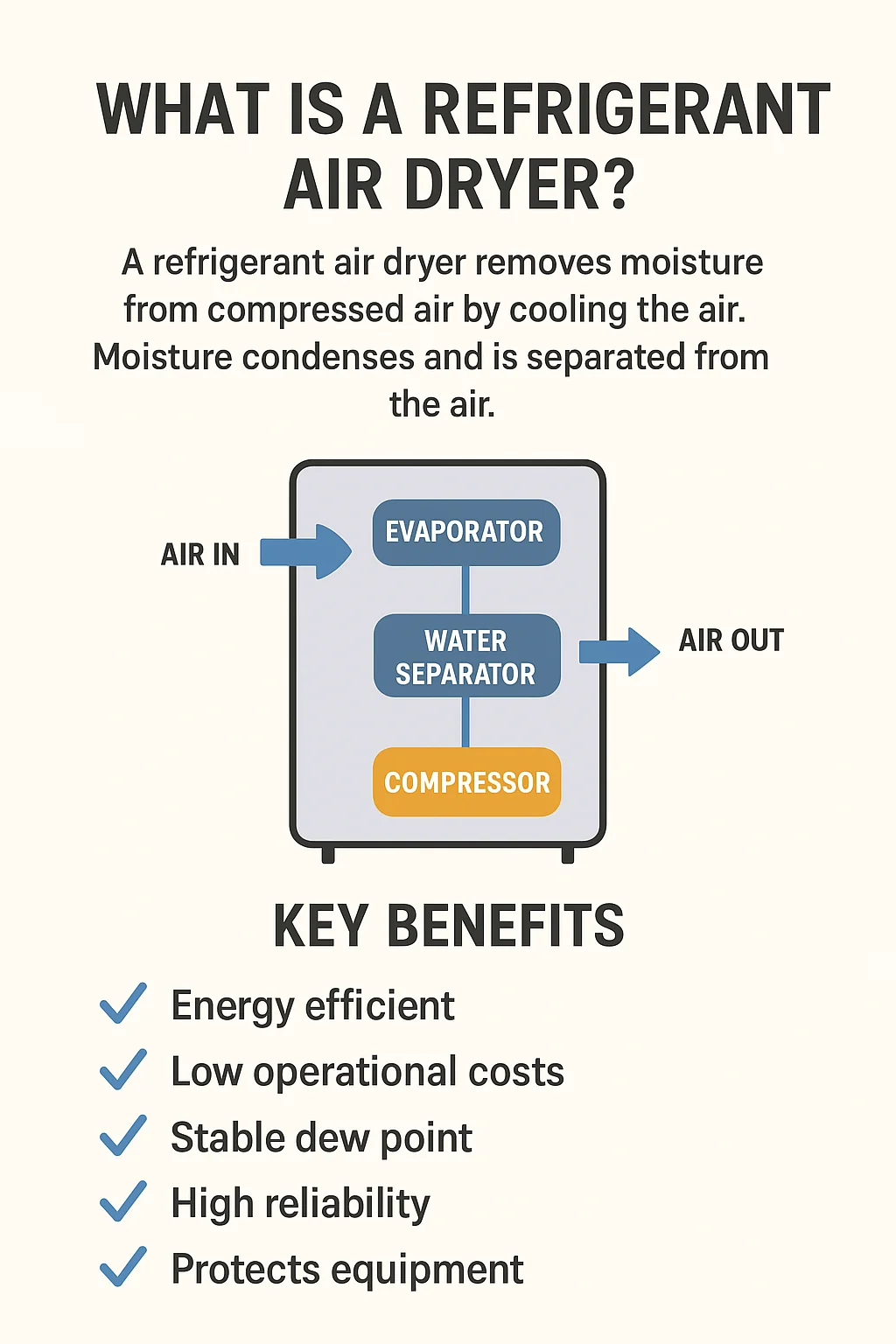

What Is a Refrigerant Air Dryer?

A refrigerant air dryer (or refrigerated air dryer) is a device that removes moisture from compressed air by cooling it. When the air is chilled, water vapor condenses into liquid droplets, which can then be separated and drained from the system.

These dryers typically achieve a dew point of around +3°C to +10°C (37°F–50°F), making them ideal for general-purpose applications where ultra-dry air isn’t required.

How a Refrigerant Air Dryer Works

Refrigerant dryers operate using the same basic principles as household refrigerators or air conditioners. Here’s a simplified breakdown of the process:

1. Warm, Moist Compressed Air Enters the Dryer

The incoming air contains high humidity and heat from compression.

2. The Air Is Cooled by a Refrigeration System

A refrigerant circulates through an evaporator coil, cooling the compressed air.

3. Moisture Condenses Into Water

As the air temperature drops, water vapor turns into liquid droplets.

4. A Separator Removes Liquid Water

The condensed moisture is collected and drained automatically.

5. Dry, Cool Air Is Reheated

The outgoing air passes through a heat exchanger to prevent pipe sweating and improve energy efficiency.

This simple yet efficient process makes refrigerant dryers extremely reliable for day-to-day operations.

Types of Refrigerant Air Dryers

There are two primary types:

1. Non-Cycling Refrigerant Dryers

Run continuously

Maintain stable dew point

Simple and cost-effective

Best for: steady production environments with constant airflow demand.

2. Cycling Refrigerant Dryers

Adjust cooling power based on load

Reduce energy consumption

Maintain performance during variable demand

Best for: facilities focused on energy savings and fluctuating air use.

Key Benefits of Using a Refrigerant Air Dryer

✔ Energy Efficient

Refrigerant dryers consume less power compared to desiccant dryers.

✔ Low Operational Costs

Minimal maintenance and no need for desiccant replacement.

✔ Stable Dew Point

Ideal for general industrial air applications.

✔ High Reliability

Simple design, fewer moving parts, and robust performance.

✔ Protects Equipment

Prevents corrosion, tool degradation, product spoilage, and unexpected downtime.

Where Are Refrigerant Air Dryers Used?

These dryers are widely used in industries such as:

Automotive workshops

Food and beverage production

Packaging and printing

CNC machining

Electronics manufacturing

General factory compressed-air systems

Pneumatic tools and robots

If your application requires clean, dry air but not ultra-low dew point levels, a refrigerant air dryer is an excellent choice.

How to Choose the Right Refrigerant Air Dryer

When selecting a dryer, consider:

Airflow capacity (CFM / m³/min)

Operating pressure and temperature

Required dew point

Energy efficiency (cycling vs non-cycling)

Drain system design

Ambient conditions

Future expansion needs

Always size your dryer slightly above your compressor’s maximum output to avoid overload.

Conclusion

A refrigerant air dryer is one of the most effective and economical ways to remove moisture from compressed air. With a reliable cooling-based drying process and low cost of ownership, it remains the most popular choice for general industrial applications.

Whether you’re upgrading your current system or designing a new one, selecting the right refrigerant air dryer will improve performance, extend equipment life, and reduce maintenance costs.