On the afternoon of December 5, 2025, Lingyu successfully held the launch event for its new Carbon-Supported Deoxygenation Purification System in Foshan, Guangdong. Centered around the theme “High Purity, High Efficiency, Energy-Saving Leadership”, the event was conducted through a combination of an offline main venue and simultaneous multi-platform online livestreaming. The launch attracted numerous industry experts, partners, and media representatives, who gathered to witness Lingyu’s latest technological breakthrough in the field of gas purification.

Addressing Industry Pain Points

Driving Technological Innovation

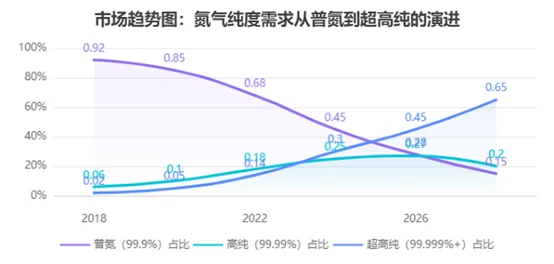

Today, with the expansion of strategic emerging industries such as semiconductors and photovoltaics, alongside the upgrading of traditional industries such as chemicals and biopharmaceuticals, demand for high-purity nitrogen has become increasingly stringent. Requirements now exceed 99.999% purity, demanding both low energy consumption and optimized operational costs.

However, traditional gas purification equipment faces three major challenges:

High energy consumption

Low purification efficiency

Narrow application scenarios

These limitations make it difficult to meet the needs of rapidly evolving industries.

As a core piece of equipment that ensures production quality and process stability, carbon-supported nitrogen purification systems are evolving toward modular integration, intelligent control, domestic substitution, and energy-efficient solutions. The project targets a technology-driven high-end market segment, directly addressing the challenges of core processes and rapid demand response, with strong market demand and high growth potential.

Leveraging years of expertise in gas separation, Lingyu’s R&D team focused on solving key purification challenges. Through multiple rounds of technical discussions and experimental validation, the team successfully developed the Carbon-Supported Deoxygenation Purification System, adopting an innovative “carbon catalytic + CO₂ module” process. This technology effectively resolves the issues of high energy consumption and unstable purity found in traditional solutions, achieving breakthroughs in high-purity output, efficient operation, and energy savings.

Committed to Innovation

Empowering Green Industry

During the keynote session, Lingyu’s Chairman Mr. Yan Wenxue delivered a speech on the theme “Transformation and Breakthrough—Winning Through Strategy.” He reviewed Lingyu’s journey: founded in 2009 in Zhongshan, Guangdong, adhering to the values of innovation, sustainability, win-win cooperation, and integrity. After three major development transformations, Lingyu has grown into a national high-tech enterprise and a Guangdong “Specialized, Refined, Distinctive, Innovative” (SRDI) company, with 40,000 m² of operating area, more than 300 employees, numerous patents, and deep university-enterprise cooperation.

Mr. Yan emphasized that under the dual-carbon policy, industrial equipment is shifting toward high-efficiency and energy-saving technologies. Lingyu will continue to drive customer value by delivering both environmental and economic benefits through innovation—aiming to achieve 800 million RMB in output within five years and build a globally recognized brand.

Technical Insights: Energy-Saving Post-Processing Solutions

Lingyu’s Technical Director Ms. Sun Yangjing presented a keynote titled “Energy-Saving Technologies in Gas Post-Processing.” She analyzed energy consumption bottlenecks in industrial gas treatment and the limitations of traditional processes.

The new Carbon-Supported Deoxygenation Purification System integrates intelligent temperature control and multi-stage adsorption coupling technologies, achieving nitrogen purity above 99.999% while optimizing energy use throughout the entire process. She also introduced the system’s modular design and full-chain energy-saving architecture, highlighting Lingyu’s capability in driving the industry’s green transformation through technological advancement.

During the Q&A session, she provided detailed answers to technical inquiries, offering participants a clearer understanding of the solution.

A Breakthrough in High-Purity Gas Technology

Setting a New Benchmark in Purification

In the core segment of the event, Product Manager Mr. Chen Long presented an in-depth explanation of the system’s technical highlights. Featuring the dual-effect “carbon catalytic + CO₂ module” process, the product delivers ultra-high purity, hydrogen-free operation, and exceptional energy efficiency—perfectly meeting the high-purity nitrogen requirements of advanced industrial upgrading.

1. Core Process Breakthrough: Dual-Effect Technology for Purity Enhancement

The combined carbon-catalytic and CO₂-removal process significantly improves purification performance.

Commercial-grade nitrogen (99.9%) undergoes reaction, impurity removal, and filtration to produce nitrogen with ≥99.999% purity, with total impurities below 1 ppm.

2. High-Level Performance Indicators: Meeting Advanced Industrial Requirements

Ultra-low impurities: O₂ ≤ 10 ppm; CO₂ ≤ 5 ppm

Deep dehydration: Dew point ≤ –60°C, ensuring dryness for precision applications

Flexible capacity: 10–800 m³/h, covering needs from laboratories to large-scale production

3. Four Key Advantages: Safe, Energy-Saving, Stable, Easy to Maintain

Hydrogen-free design for maximum safety

Eliminates explosion risks associated with hydrogen-based purification, ideal for electronics, pharmaceuticals, and hydrogen-sensitive sectors.Up to 30% energy savings

Waste-heat recovery significantly reduces power consumption and lowers operating costs.Dual-tower structure for continuous, stable output

Allows online catalyst replacement without interrupting production.Intelligent control for simplified maintenance

Equipped with Siemens PLC, enabling fully automatic operation and fault alerts.

Catalyst lasts up to 120 days, with no residue after depletion—adding new material directly saves time and labor.

4. Precision Components: Building Long-Term Reliability

Deoxygenation towers designed to GB150 pressure vessel standards, withstanding ≥400°C

Key components comply with JB/T2379-93 industrial standards

Enhanced airflow distribution with perforated bottom plates

Imported sensors and a 40,000-record data log for traceable purity tracking

A product display zone was set up at the event, allowing guests to observe the equipment up close.

Lucky Draw Ignites Excitement

A Successful Conclusion

At the end of the event, an exciting lucky draw brought the atmosphere to a climax. Guests eagerly participated, with applause and cheers filling the venue. Meanwhile, online viewers also joined the interaction, with over 7,000 participants engaging through live comments.

With the announcement of the grand prize winner, the product launch concluded successfully. The Lingyu team expressed heartfelt gratitude to all guests, online viewers, and partners:

“Your interest and support make this technological event meaningful, and your trust gives us the strength to keep innovating.”

A Milestone Debut

Shaping the Future of High-Purity Gas Purification

This launch event marked not only the debut of the Carbon-Supported Deoxygenation Purification System but also an important message from Lingyu to the industry. Moving forward, the company will continue to place customer needs at the center, deepen research in gas purification technologies, and continuously upgrade its product and service systems. With more efficient and energy-saving solutions, Lingyu aims to support global industrial enterprises in achieving green transformation and to build a sustainable future together with partners worldwide.