The Essential Guide to Desiccant Air Dryers for Compressed Air

Compressed air is a cornerstone of many industrial processes, from manufacturing to food processing and electronics. However, one of the most common challenges in compressed

Lingyu’s advanced desiccant air dryers are engineered to provide robust equipment protection and peak performance. By removing all traces of moisture, our desiccant dryers ensure your compressed air system operates smoothly, reducing downtime and boosting productivity.

Our industrial desiccant air dryers deliver ultra-low dew points (-40°C to -70°C / -40°F to -94°F), making them ideal for moisture-sensitive processes in pharmaceuticals, electronics, food & beverage, petrochemicals, and other demanding industries.

Explore our full range of desiccant air dryers below and request a quote to select the ideal solution for your compressed air system.

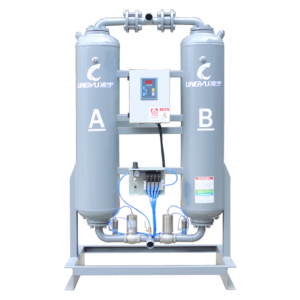

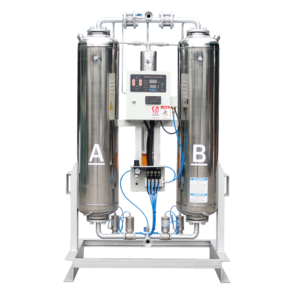

Quiet operation with low noise;

Utilizes high-performance pneumatic valves;

Equipped with a fully electronic programmable controller;

Automatic pressure loading function ensures the longevity of the desiccant;

Heater includes pressure protection to prevent dry burning, extending the heater’s service life;

Uses high-performance desiccant with strong adsorption and wear resistance, ensuring stable dew point and preventing powdering during long-term operation.

Integrated design: small footprint, easy to install, after years of technical research, modern technology and equipment production, each product is strictly tested to meet the use of standards before leaving the factory.

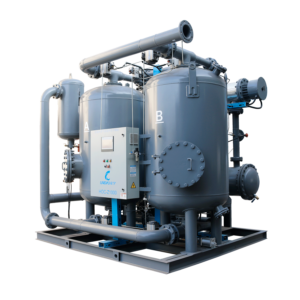

The Blower & Zero Purge Adsorption Dryer is an advanced solution for industrial compressed air systems, designed to provide continuous, energy-efficient moisture removal.

This dryer combines blower-assisted regeneration with a zero purge cycle, ensuring the regeneration process consumes no compressed air. Ambient air is drawn in by the blower, heated to desorb moisture from the adsorbent, and then cooled through an intermediate cooler in a continuous closed-loop cycle. The result is a stable low dew point with minimal energy usage, protecting downstream equipment and ensuring consistent air quality in industrial operations.

Desiccant air dryers are industrial devices designed to achieve extremely low dew points by adsorbing moisture from compressed air. Using high-quality desiccant materials, our dryers remove water vapor efficiently, delivering ultra-dry air essential for sensitive processes.

Desiccant air dryers enhance the quality, reliability, and safety of compressed air systems. They protect both equipment and final products by preventing moisture-related issues.

Ultimate Moisture Protection: Achieve ultra-low dew points to prevent liquid water formation in pipelines, protect pneumatic tools, and ensure consistent product quality.

Ensuring Product Integrity: Even microscopic moisture can compromise sensitive manufacturing processes. Our desiccant dryers guarantee consistently clean, dry air to safeguard your production line.

Maximizing System Uptime: Dry air improves the reliability and longevity of your compressed air system, reducing maintenance needs and preventing costly downtime.

Compliance with Industry Standards: Advanced technology ensures adherence to strict industrial and safety regulations requiring ultra-dry air, providing operational security and peace of mind.

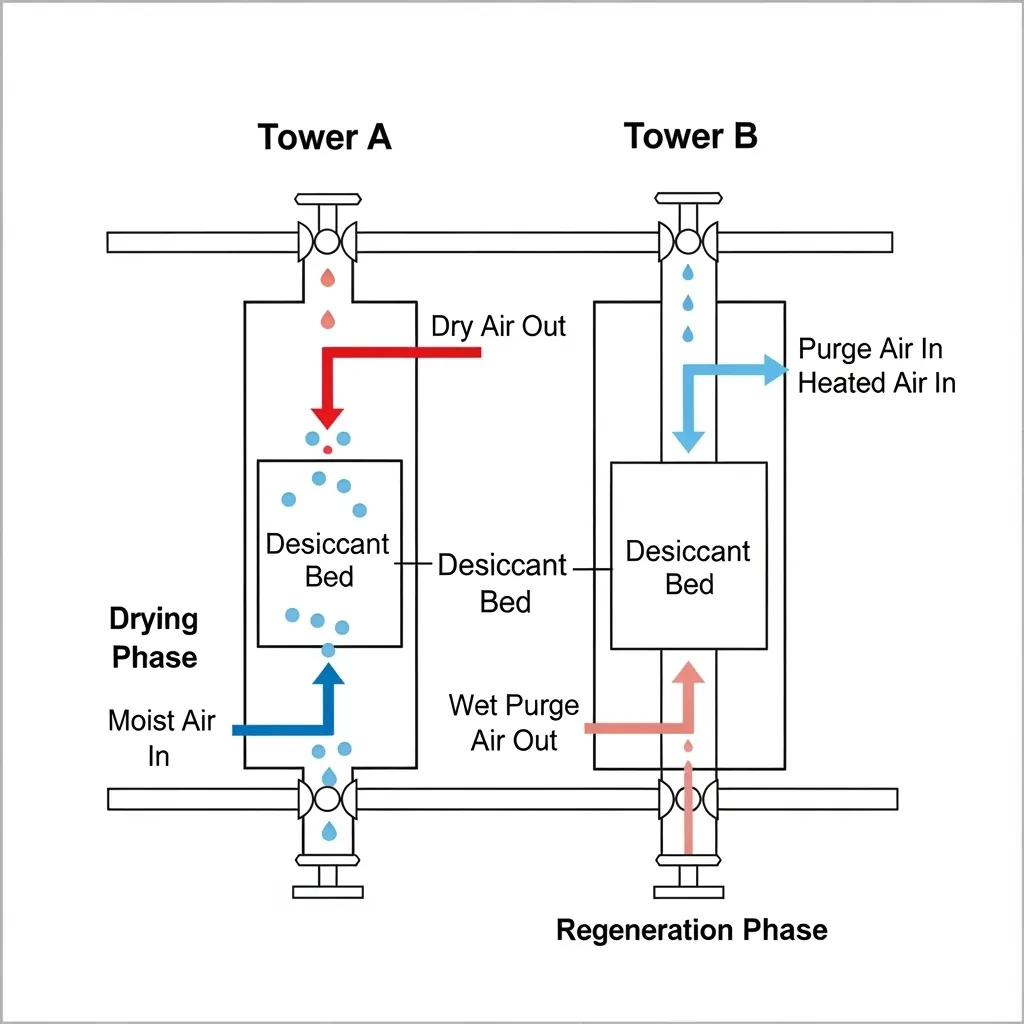

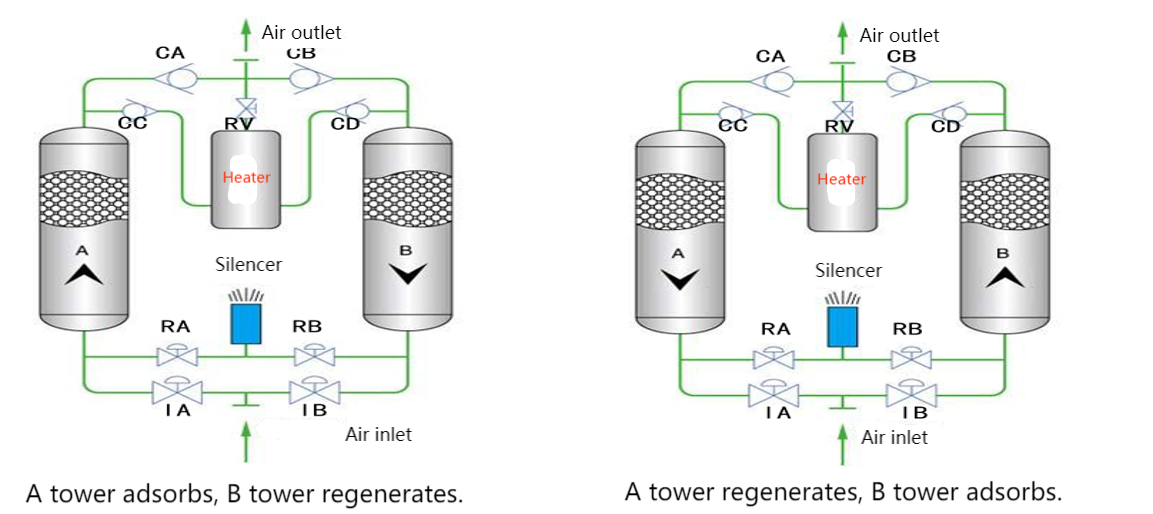

Desiccant air dryers operate on the principle of adsorption, typically using a dual-tower configuration for continuous operation.

Moist compressed air enters one tower packed with high-quality desiccant material such as activated alumina or silica gel. The desiccant captures water vapor, lowering the dew point to the desired level. The now-dry air exits the tower and continues downstream to your system.

While one tower dries the air, the second tower regenerates the desiccant by expelling absorbed moisture. Depending on the dryer type (heatless, blower-heated, or compression-heated), regeneration is achieved using a portion of dry air or an external heat source.

Our control system automatically manages tower cycling, ensuring one tower is always in operation while the other regenerates. This provides a constant supply of ultra-dry compressed air without interruption.

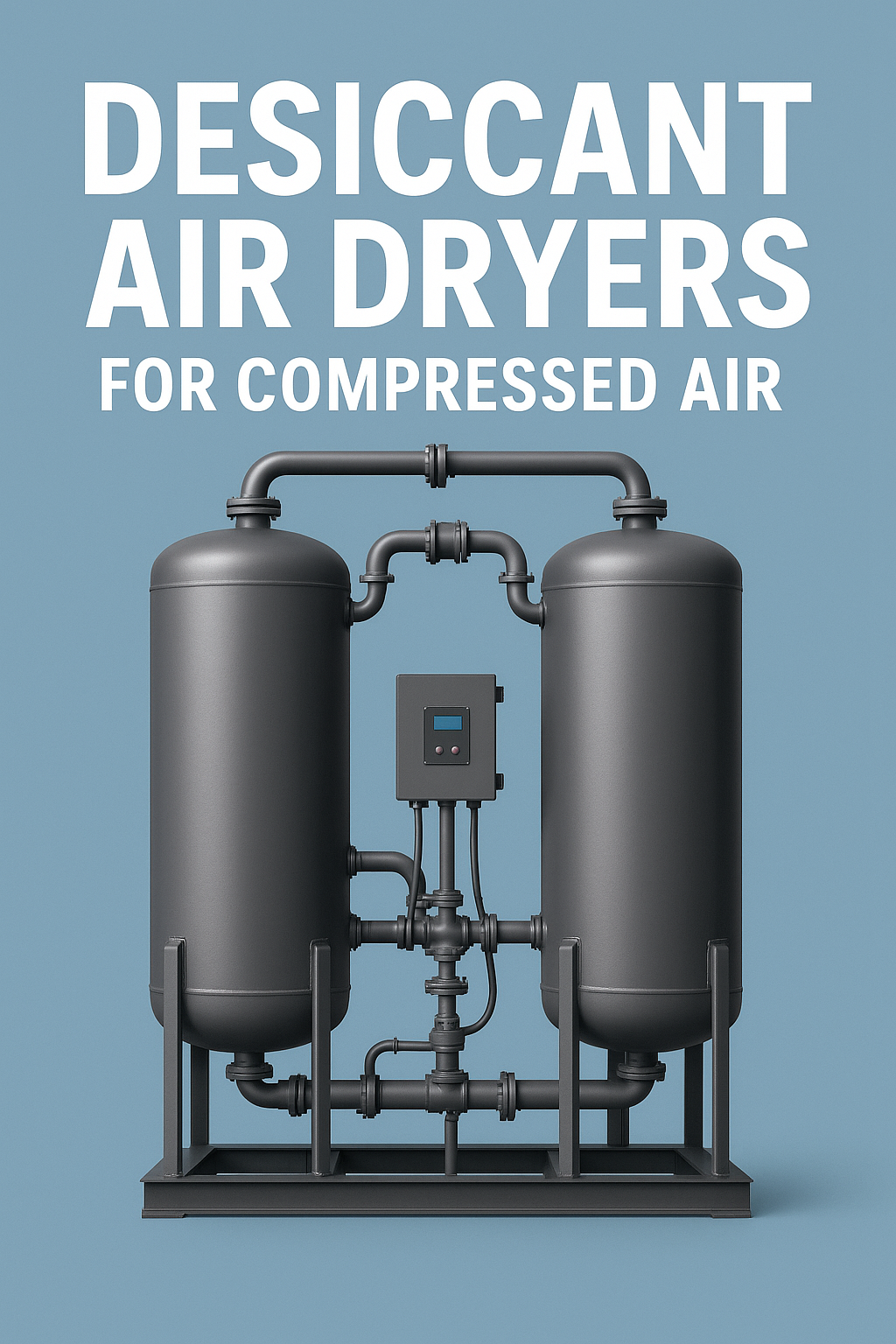

Lingyu offers a comprehensive range of desiccant air dryers, each engineered to meet specific operational and industrial requirements.

These dryers use a portion of dried compressed air to regenerate the desiccant without external heat. They are robust, low-maintenance, and ideal for lower-duty applications or simple, reliable drying needs.

Engineered for superior energy efficiency, these dryers use external heat to minimize purge air consumption. Our lineup includes Blower-Heated and Compression-Heated models, maximizing energy savings and performance for higher-volume applications.

Compact and scalable, modular desiccant dryers are perfect for smaller footprints or operations requiring flexible expansion. Their design simplifies installation and maintenance while delivering reliable ultra-dry air for growing businesses or space-limited environments.

No.3, 2nd Street, yuanle Road, Dongsheng Town, Zhongshan City, Guangdong Province

(WeChat/WhatsApp):+8615756650906

№1:(WeChat/WhatsApp):+8618628146428

№2:(WeChat/WhatsApp):+8613823294942

Compressed air is a cornerstone of many industrial processes, from manufacturing to food processing and electronics. However, one of the most common challenges in compressed

Understanding the Desiccant Air Dryer Working Principle Why Dry Compressed Air Matters Compressed air is a vital utility in manufacturing, healthcare, electronics, food processing, and

Introduction: Why You Need an Industrial Desiccant Air Dryer Compressed air systems are the backbone of countless industrial operations. But one invisible enemy threatens their

Introduction: Why a Desiccant Air Dryer for Air Compressor Is Essential In industries where moisture-free air is critical, the desiccant air dryer for air compressor