In this guide, we will explain why air dryer desiccant replacement is necessary, how to know when it’s time for a change, and the steps you can take to ensure that your air dryer continues working effectively.

What is Air Dryer Desiccant?

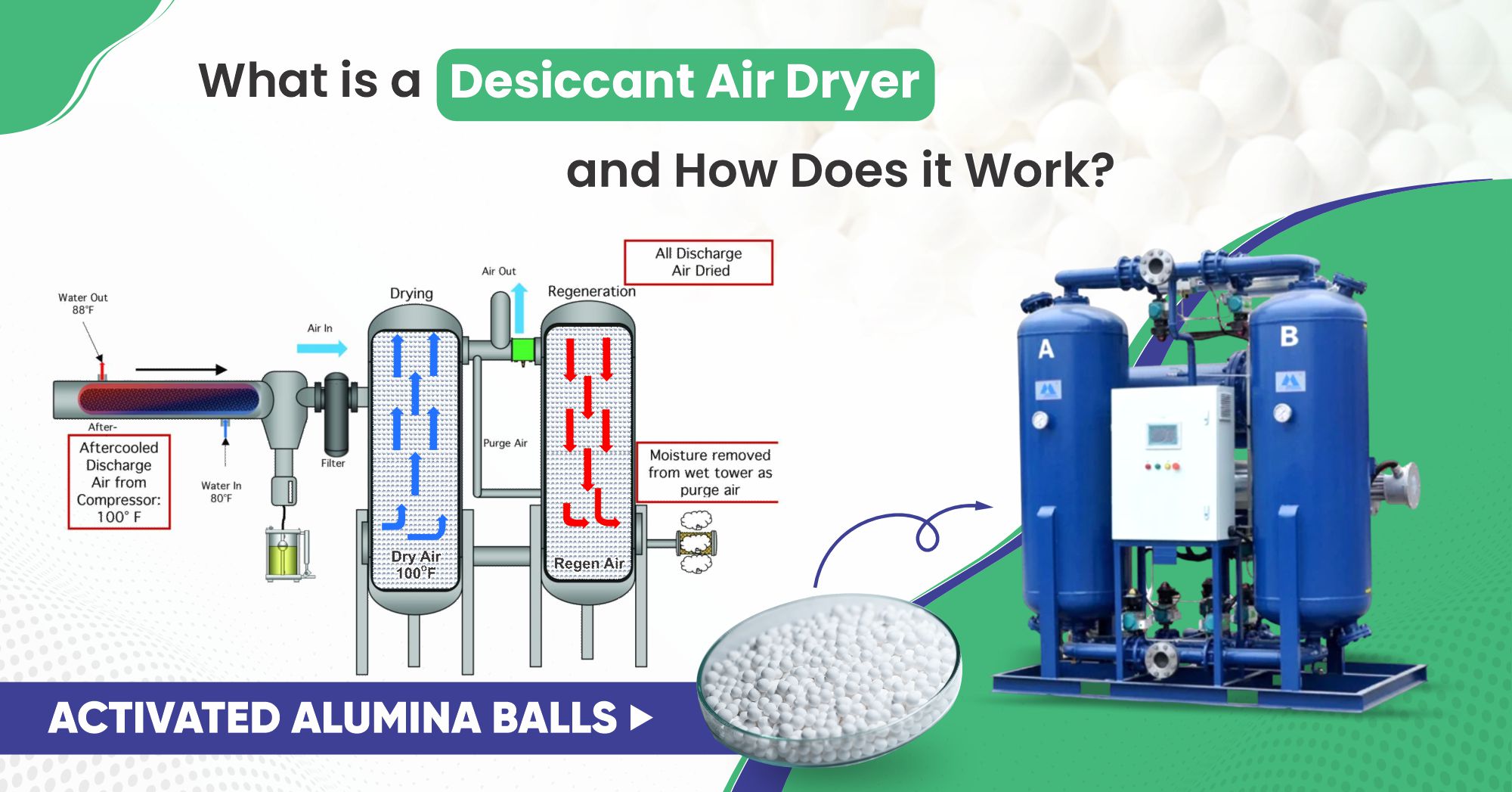

An air dryer desiccant is a material used in compressed air dryers to remove moisture from the air. The desiccant absorbs water vapor from the air, ensuring that only dry air is passed through the system. There are several types of desiccants, including silica gel, activated alumina, and molecular sieves, each with varying capacities for moisture absorption.

Desiccant materials work in cycles, absorbing moisture during one phase and releasing it during the regeneration process. Over time, however, these materials become saturated and lose their ability to absorb moisture, which is why air dryer desiccant replacement is necessary.

Why is Air Dryer Desiccant Replacement Important?

Desiccants are essential for preventing moisture-related problems in compressed air systems. Without proper desiccant maintenance, your system may experience:

1. Corrosion:

Moisture can lead to rust and corrosion in pipes, valves, and other components of your compressed air system. Replacing desiccants on time helps prevent this damage.

2. Reduced Efficiency:

As desiccants become saturated with moisture, they lose their effectiveness, leading to decreased dryer efficiency. This results in a higher energy consumption and more frequent maintenance.

3. Contaminated Air:

If the desiccant is not replaced, it may release absorbed moisture back into the air, contaminating the system and affecting the products or processes relying on clean air.

4. Increased Downtime:

When desiccants fail to perform effectively, your system may experience more frequent breakdowns, leading to costly repairs and unplanned downtime.

5. Shortened Equipment Lifespan:

Excess moisture can shorten the lifespan of your entire compressed air system. Regular desiccant replacement helps protect your investment.

How Often Should You Replace Air Dryer Desiccant?

The frequency of air dryer desiccant replacement depends on several factors, including the type of desiccant, the amount of moisture in the compressed air, and the operating conditions. Typically, desiccant materials need to be replaced every 2-5 years, but this can vary depending on usage.

Signs That Your Desiccant Needs Replacement:

Reduced Dry Air Quality: If you notice that the air produced by your dryer is no longer consistently dry or that the system is producing moisture-laden air, it’s a sign the desiccant may need replacing.

Increased Energy Consumption: Saturated desiccants require more energy to regenerate, leading to higher electricity bills.

Frequent System Breakdowns: If your air dryer is frequently breaking down or requiring maintenance, it may indicate that the desiccant is no longer functioning properly.

Physical Degradation: Inspect the desiccant regularly. If you see any cracks, discoloration, or signs of wear, it’s time for a replacement.

Steps to Replace Air Dryer Desiccant

Replacing air dryer desiccant is a straightforward process, but it’s important to follow the correct steps to ensure the new desiccant performs optimally.

1. Shut Down the System:

Before beginning the replacement process, ensure that the air dryer is powered down and the system is depressurized to avoid accidents.

2. Remove the Old Desiccant:

Carefully remove the old desiccant material from the dryer. Be sure to wear protective gloves and eyewear during this step, as the desiccant may be dusty or hazardous.

3. Clean the Dryer:

Before installing the new desiccant, thoroughly clean the dryer to remove any debris, moisture, or contaminants. This helps ensure the longevity of the new desiccant.

4. Install the New Desiccant:

Place the fresh desiccant into the dryer. Be sure to follow the manufacturer’s guidelines for the correct amount and type of desiccant.

5. Regeneration and Testing:

After installing the new desiccant, regenerate the dryer as instructed and test it to ensure it’s functioning correctly. Check for any leaks or abnormal performance.

Choosing the Right Desiccant for Your Air Dryer

When performing air dryer desiccant replacement, selecting the right type of desiccant is essential for ensuring that your air dryer operates efficiently. Here are some popular desiccant materials:

1. Silica Gel:

Silica gel is a common desiccant due to its high moisture absorption capacity. It is ideal for low-to-moderate moisture levels and is often used in general industrial applications.

2. Activated Alumina:

Activated alumina is a more robust desiccant that can absorb more moisture and handle higher humidity levels. It is commonly used in applications that require high-efficiency dryers.

3. Molecular Sieves:

Molecular sieves are designed for high-performance air drying and can remove moisture even in extremely low humidity conditions. They are ideal for specialized industries, such as pharmaceuticals or electronics.

FAQ: Air Dryer Desiccant Replacement

1. How do I know when my desiccant needs replacing?

You can monitor your system’s performance, energy consumption, and dry air quality. If you notice any degradation in performance, increased moisture in the air, or higher energy bills, it’s time for desiccant replacement.

2. Can I replace desiccant materials myself?

Yes, replacing desiccants is a manageable task if you follow proper procedures. However, it’s recommended to consult the manufacturer’s guidelines or contact a professional if you are unsure.

3. How do I properly dispose of old desiccant material?

Desiccant materials, like silica gel or activated alumina, are typically non-toxic, but it’s best to dispose of them according to local regulations. Some desiccants may be recyclable.

4. What happens if I don’t replace the desiccant?

If you fail to replace desiccant material, the dryer will become less effective at removing moisture, leading to contamination, system corrosion, and higher maintenance costs.

5. How long does the desiccant replacement process take?

The process usually takes a few hours, depending on the size of the air dryer and the type of desiccant used.

Benefits of Regular Air Dryer Desiccant Replacement

Regular air dryer desiccant replacement offers numerous benefits, including:

Improved System Performance: Ensures the air dryer maintains its efficiency in moisture removal, keeping your compressed air clean and dry.

Cost Savings: By avoiding moisture-related damage and reducing energy consumption, you can save on repair and operational costs.

Compliance: Many industries have strict regulations for clean and dry compressed air. Regular desiccant replacement helps ensure compliance with these standards.

Conclusion

Air dryer desiccant replacement is a crucial aspect of maintaining a functional, energy-efficient compressed air system. By understanding when and how to replace desiccants, and by choosing the right material for your specific needs, you can ensure that your system operates at its best for years to come.

Regular air dryer desiccant replacement will not only improve the performance of your system but will also help prevent costly repairs and downtime. Take the necessary steps to replace your desiccants on time and keep your compressed air system running smoothly.

Related products:

2, Minimum regeneration gas consumption

3. Long service life of adsorbent

4. Easy maintenance

5. High safety

6. High reliability

7.Adjustable regeneration gas consumption

8. Optional dew point monitoring and control system

2. Resists chemical corrosion and extends service life

3. Special sealing technology prevents flammable gases or dust from entering theinterior of the machine

4. Regeneration gas consumption can be adjusted, with energy saving and dewpoint adjustment function

2, Customized high-performance adsorbent, 20% filling margin;

3. Branded high-pressure blower, high-performance pneumatic valve, high-efficiency cooler designed by HTFS software, reliable performance and long life;

4. 304 stainless steel control gas pipeline, specially designed diverter, highadsorbent utilization rate and low gas pressure loss;