PSA Nitrogen Generator vs Cryogenic Nitrogen Generator: A Comprehensive Comparison

With industrial demand for nitrogen growing at around 8% annually in China and globally, choosing the right nitrogen generation technology matters more than ever. Two leading methods—cryogenic nitrogen generators and PSA nitrogen generators (Pressure Swing Adsorption)—offer unique benefits suited to different industrial scenarios. This article dives into those differences, focusing on the strengths of the PSA nitrogen generator.

What Is a Cryogenic Nitrogen Generator?

Cryogenic nitrogen generators produce nitrogen through low-temperature fractional distillation of liquefied air—typically at temperatures below -190 °C. This method separates nitrogen from liquid oxygen with extremely high purity, often up to 99.9995%.

Key Advantages:

Ultra-high purity nitrogen output ideal for semiconductor, pharmaceutical, and analytical applications.

Produces both gaseous and liquid nitrogen, useful for flash freezing or backup storage.

Challenges:

High capital investment due to complex cryogenic equipment and infrastructure.

Long installation time and increased maintenance costs for low-temperature systems.

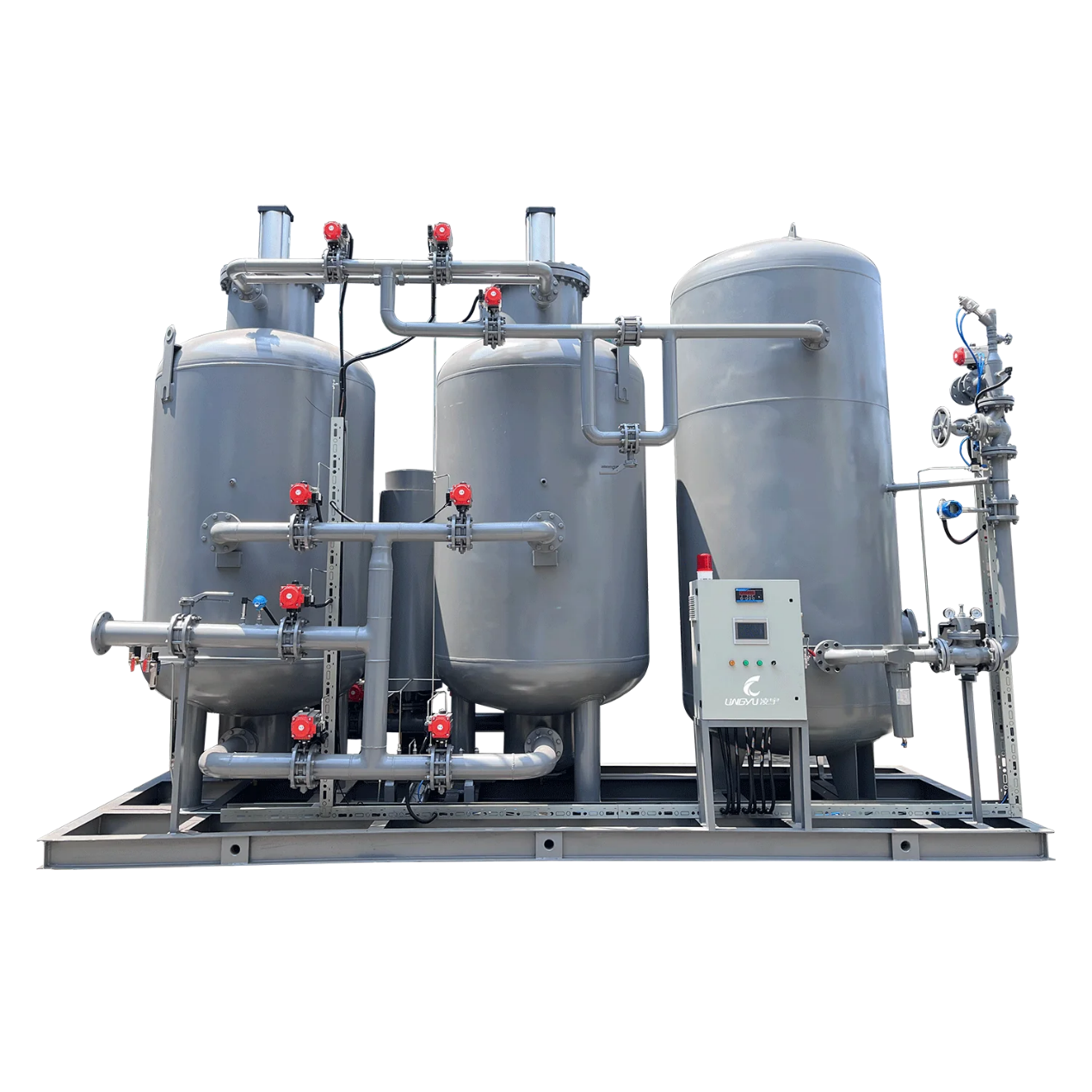

What Is a PSA Nitrogen Generator?

A PSA nitrogen generator (Pressure Swing Adsorption) separates nitrogen from compressed air using selective adsorption materials—commonly carbon molecular sieve (CMS)—under fluctuating pressures. Nitrogen is collected during the high-pressure phase while adsorbents release impurities when pressure lowers.

PSA Nitrogen Generator Advantages

1. Lower Cost & Energy Efficiency

Compared to cryogenic systems, PSA nitrogen generators are more energy- and cost-efficient. They require no liquid cooling systems and expend significantly less energy per produced cubic meter of nitrogen.

2. Flexible Purity and Output

PSA systems offer adjustable purity levels—typically between 95% to 99.999%—and can adapt flow rate quickly to match production needs. Startup times are short, making them highly responsive.

3. Simpler, Lower-Maintenance Design

These systems run at near-ambient temperatures and utilize fewer mechanical elements, meaning easier maintenance, lower downtime, and reduced operating costs.

4. Higher Energy Savings and ROI

Studies show PSA systems require roughly 0.3–0.5 kWh per Nm³ of nitrogen at 99% purity, highlighting their high energy efficiency for small to medium-scale users.

Cryogenic System Benefits

Provides ultra-high purity nitrogen and liquid nitrogen suitable for critical industries.

Best for large-scale, high-purity production, such as steel manufacturing and large chemical plants.

Delivers high-capacity, consistent output—but at a high operating and maintenance cost.

How to Choose Between PSA and Cryogenic Generators?

| Criteria | Cryogenic Nitrogen Generator | PSA Nitrogen Generator |

|---|---|---|

| Nitrogen Purity | Up to 99.9995% | Adjustable: 95%–99.999% |

| Liquefied Nitrogen Option | Yes | No |

| Investment & Installation | High | Moderate |

| Energy Consumption | Higher due to refrigeration needs | Lower, efficient adsorption-based processing |

| Flexibility & Scalability | Best for fixed, ultra-high demand | Highly adaptable to variable flows/purities |

| Maintenance Requirements | Complex, requires cryogenic expertise | Simpler, suitable for in-house maintenance |

| Best Applications | Large-scale, ultra-high purity needs | Mid-size industries, cost-sensitive environments |

Applications at a Glance

Cryogenic Generators: Industries demanding ultra-purity or liquid nitrogen—semiconductor fabs, research institutions, cryogenics.

PSA Nitrogen Generators: Ideal for electronics manufacturing, food packaging, pharmaceuticals, and general industrial applications.

PSA Nitrogen Generator vs Cryogenic

Can PSA reach the same purity as cryogenic systems?

PSA can reach up to 99.999% purity, suitable for most applications. Cryogenic systems offer slightly higher purity but only necessary in rare cases.

Are PSA systems more cost-effective?

Yes. PSA units require less infrastructure and energy, making them more economical, especially for mid-volume systems.

Do PSA generators produce liquid nitrogen?

No. PSA systems generate only gaseous nitrogen. Only cryogenic systems provide liquid nitrogen.

Which tech is better for small to medium demand?

PSA systems outperform cryogenic by balancing cost, purity, and flexibility for 200–3000 Nm³/h ranges.

Are PSA systems environmentally friendly?

Absolutely. PSA avoids high-energy refrigeration or liquid nitrogen transport, reducing emissions and energy use.

Conclusion

When comparing options, the PSA nitrogen generator provides excellent flexibility, lower costs, and scalability—ideal for dynamic and mid-scale industrial needs.

In contrast, cryogenic nitrogen generators excel when ultra-high purity or liquid nitrogen is required at massive scale.

Your choice should reflect your industry’s demands: purity, output size, budget, and operational agility. For most modern manufacturers, the PSA nitrogen generator delivers unmatched value, making it a smart, efficient solution.

Related products:

Nitrogen generator with 99.99% purity—reliable, efficient, and built for demanding industrial applications.