Understanding the Desiccant Air Dryer Working Principle

Why Dry Compressed Air Matters

Compressed air is a vital utility in manufacturing, healthcare, electronics, food processing, and many other industries. However, untreated compressed air contains significant moisture, which can cause:

Equipment corrosion

Downtime due to component failure

Damaged or contaminated products

Reduced production efficiency

To eliminate these risks, companies rely on desiccant air dryers, especially in environments where ultra-dry air is critical. Understanding the desiccant air dryer working principle is essential for selecting, operating, and maintaining these systems effectively.

What Is a Desiccant Air Dryer?

A desiccant air dryer is a type of compressed air drying equipment that uses adsorption to remove moisture from the air stream. Unlike refrigerated air dryers, which cool air to condense water, desiccant dryers capture water vapor directly using a moisture-absorbing material called desiccant.

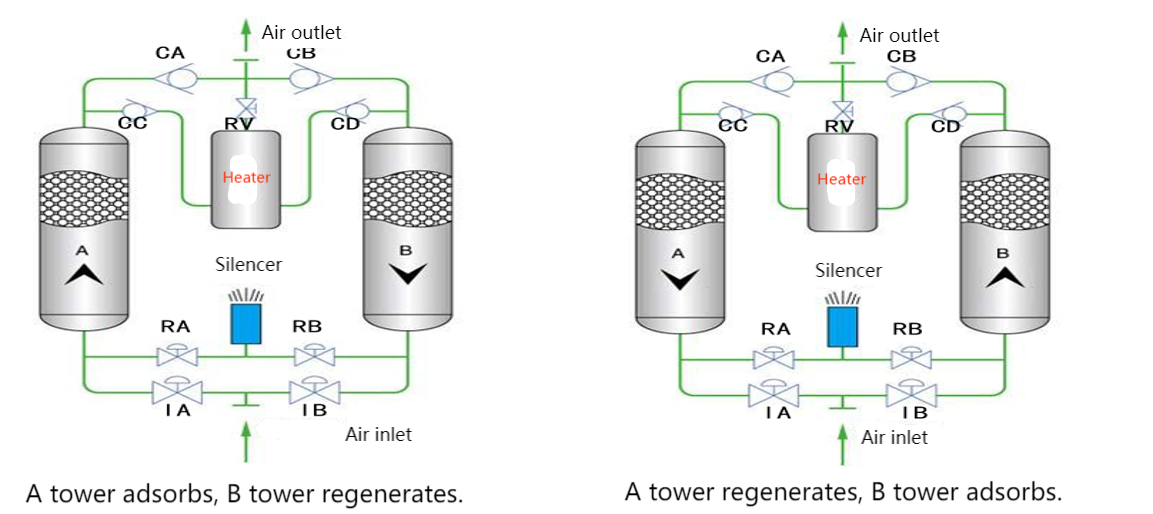

The desiccant air dryer working principle is based on alternating adsorption and regeneration cycles, typically using a twin-tower system.

Desiccant Air Dryer Working Principle Explained

The desiccant air dryer working principle involves several stages. Here’s a detailed breakdown:

1. Adsorption Phase (Drying Process)

Compressed air flows into the drying tower filled with desiccant (such as activated alumina or molecular sieve). The desiccant adsorbs water vapor from the air, allowing dry air to exit with a dew point as low as -40°F (-40°C) or even -100°F (-73°C).

2. Regeneration Phase (Desiccant Drying)

As the desiccant becomes saturated with moisture, the system automatically switches towers. While one tower dries the air, the other undergoes regeneration—removing the accumulated moisture to restore its drying capacity.

3. Tower Switching

A programmable controller manages the cycling between towers to ensure continuous drying. The cycle time depends on system design and application requirements.

H2: Types of Regeneration Methods

The regeneration process is a critical part of the desiccant air dryer working principle. There are several types:

🔹 Heatless Desiccant Air Dryer

Uses a portion of the dried air to purge moisture from the saturated tower

Energy-efficient and reliable, with no heating elements

Ideal for compact, low-maintenance installations

🔹 Heated Desiccant Air Dryer

Utilizes electric heaters to regenerate desiccant

Requires less purge air than heatless models

Suitable for higher air demand environments

🔹 Blower Purge Desiccant Air Dryer

Uses a blower and external heat source to regenerate without purge air

Ideal for energy-conscious facilities with large flow rates

🛠️ Key Technical Features of Desiccant Air Dryers

| Feature | Specification |

|---|---|

| Operating Pressure | 4–10 bar (up to 16 bar optional) |

| Inlet Temperature | Up to 120°F / 150°F (with aftercooler) |

| Pressure Dew Point | -40°F to -100°F |

| Flow Range | 20 CFM to 5000+ CFM |

| Control System | PLC with HMI display and dew point monitoring |

| Desiccant Media | Activated Alumina / Molecular Sieve |

🌟 Marketing Recommendation: Get the Ultimate Moisture Protection

Don’t let moisture ruin your compressed air system.

With the advanced desiccant air dryer working principle, you can ensure ultra-dry air for even the most sensitive applications. Whether you’re operating in sub-zero environments or running precision machinery, our industrial-grade desiccant air dryers provide unmatched reliability, low dew points, and long-lasting performance.

Order now and experience the next level of air purity. Your equipment—and your bottom line—will thank you.

Applications That Demand Desiccant Air Dryers

The desiccant air dryer working principle makes this technology suitable for:

🏭 Pharmaceutical Manufacturing – Moisture can compromise sterile environments

🚗 Automotive Paint Shops – Prevent fisheyes and finish defects

🔬 Medical Laboratories – Ensure dry air for analytical instruments

🧊 Food & Beverage Industry – Protect packaging and reduce spoilage

⚙️ CNC & Pneumatic Tools – Reduce wear and improve lifespan

🏗 Outdoor Construction Sites – Works reliably in freezing temperatures

Advantages of the Desiccant Air Dryer Working Principle

✅ Ultra-low dew points for moisture-sensitive applications

✅ Non-refrigerated—ideal for cold climates

✅ Redundant drying via twin-tower design

✅ Flexible regeneration methods based on energy needs

✅ Scalable performance from 20 CFM to 5000+ CFM

Maintenance Tips for Peak Efficiency

Understanding the desiccant air dryer working principle helps ensure proper maintenance:

🔧 Replace desiccant every 12–24 months

🔧 Monitor dew point trends for early warnings

🔧 Clean/replace filters regularly to avoid contamination

🔧 Check for valve leakage or improper switching

🔧 Maintain heater and blower components if applicable

Frequently Asked Questions (FAQ)

Q1: What is the key benefit of the desiccant air dryer working principle?

It provides ultra-dry air with dew points as low as -100°F, making it perfect for critical or cold-weather operations.

Q2: How often should I replace the desiccant?

Typically every 12 to 24 months, depending on usage, air quality, and dryer design.

Q3: Can a desiccant air dryer be used with an oil-lubricated compressor?

Yes, but it requires a coalescing pre-filter to remove oil before air enters the dryer.

Q4: Is a refrigerated dryer better than a desiccant dryer?

It depends on the dew point you need. Refrigerated dryers are suitable for general use; desiccant dryers are required for ultra-dry air or extreme environments.

Q5: Can I install the dryer outdoors?

Only if it’s housed in a weatherproof enclosure. Otherwise, indoor installation is recommended.

Conclusion: Master the Science of Dry Air

The desiccant air dryer working principle is a proven method for achieving the driest compressed air possible. By using adsorption, twin-tower cycling, and intelligent regeneration methods, these dryers offer:

Maximum moisture removal

Long operational lifespan

Energy-efficient performance

Support for critical applications across industries

If moisture is hurting your process or product quality, don’t compromise. Choose a system that’s designed with precision and powered by science.

📞 Need help choosing the right dryer?

We offer free system consultations and custom sizing to match your flow rate, dew point, and regeneration requirements.

Related products:

2, Minimum regeneration gas consumption

3. Long service life of adsorbent

4. Easy maintenance

5. High safety

6. High reliability

7.Adjustable regeneration gas consumption

8. Optional dew point monitoring and control system

2. Resists chemical corrosion and extends service life

3. Special sealing technology prevents flammable gases or dust from entering theinterior of the machine

4. Regeneration gas consumption can be adjusted, with energy saving and dewpoint adjustment function

2, Customized high-performance adsorbent, 20% filling margin;

3. Branded high-pressure blower, high-performance pneumatic valve, high-efficiency cooler designed by HTFS software, reliable performance and long life;

4. 304 stainless steel control gas pipeline, specially designed diverter, highadsorbent utilization rate and low gas pressure loss;