Desiccant air dryers for compressed air are essential components in industrial systems that require ultra-dry, moisture-free air. Unlike refrigerated dryers, desiccant air dryers use advanced adsorption technology to remove water vapor, delivering a consistent pressure dew point as low as -40°C or even -70°C.

Ideal for sensitive operations such as pharmaceuticals, electronics, food processing, and precision manufacturing, our desiccant air dryers for compressed air offer unmatched performance, reliability, and energy efficiency.

Key Features of Desiccant Air Dryers for Compressed Air

✅ Ultra-Low Dew Point: Achieve pressure dew points down to -40°C/-70°C, protecting equipment from corrosion, freezing, and moisture-related failures.

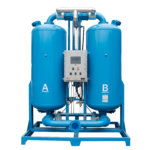

✅ Dual Tower Design: Alternating adsorption and regeneration towers ensure continuous operation with no downtime.

✅ Energy-Saving Control: Equipped with dew point controllers and purge-saving technology to reduce compressed air loss.

✅ Robust Construction: Industrial-grade steel vessels, ASME or CE certified, with corrosion-resistant inner linings.

✅ Simple Maintenance: Easy access to desiccant beds, valves, and filters minimizes maintenance time.

✅ Modular Configuration: Scalable solutions for air flow capacities from 5 CFM to 10,000+ CFM.

Our desiccant air dryers for compressed air are built to handle extreme applications that demand stable, dry air—anytime, anywhere.

Operating Conditions & Technical Requirements

Inlet Air Pressure: 4 – 10 bar (58 – 145 psi)

Inlet Air Temperature: ≤ 45°C (113°F)

Ambient Temperature: 5 – 50°C (41 – 122°F)

Max Dew Point: Down to -70°C (-94°F)

Regeneration Method: Heatless / Heated / Blower Purge (optional)

Power Supply: 220V/1Ph/50Hz or 380V/3Ph/50Hz (customizable)

Our desiccant air dryers for compressed air operate efficiently even in harsh industrial conditions, ensuring uninterrupted performance.

Technical Specifications (Example: 100 CFM Unit)

| Model | DAD-100 |

|---|---|

| Air Capacity | 100 CFM |

| Dew Point | -40°C (Standard) / -70°C (Optional) |

| Pressure Range | 4 – 10 bar |

| Desiccant Type | Activated Alumina / Molecular Sieve |

| Regeneration Type | Heatless / Heated (Optional) |

| Power Consumption | 60W – 1.5kW (depends on model) |

| Inlet/Outlet Size | 1” BSP / NPT |

| Dimensions (L×W×H) | 900 × 600 × 1200 mm |

| Weight | 180 kg |

We offer a complete range of desiccant air dryers for compressed air to meet various system capacities and moisture control demands.

Application Scenarios

Our desiccant air dryers for compressed air are widely used in industries where dry air is non-negotiable:

🧪 Pharmaceutical & Biotech – Ensures clean-room and packaging integrity

💻 Electronics & Semiconductors – Prevents moisture-related short circuits

🧼 Food & Beverage – Meets hygiene standards in production and packaging

🛢️ Oil & Gas / Petrochemicals – Protects instruments, pipelines, and pneumatic controls

🏭 Automotive & Aerospace – Assures surface quality in painting and assembly lines

🧯 Fire Protection Systems – Prevents corrosion in dry-pipe sprinkler systems

❄️ Cold Climate Installations – Prevents freeze-ups in outdoor compressed air lines

FAQ – Desiccant Air Dryers for Compressed Air

Q1: What are desiccant air dryers for compressed air used for?

A: They are used to remove moisture from compressed air in critical applications where dry air is essential to prevent corrosion, freezing, or process contamination.

Q2: What is the difference between refrigerated and desiccant air dryers?

A: Refrigerated dryers cool the air to condense moisture, while desiccant air dryers for compressed air use adsorption to remove vapor, achieving much lower dew points.

Q3: What is the typical dew point achieved?

A: Our desiccant air dryers for compressed air can reach -40°C as standard and -70°C as optional.

Q4: How often should the desiccant be replaced?

A: Depending on usage and environment, desiccants typically last 1–3 years before replacement is needed.

Q5: Do you offer custom solutions for larger systems?

A: Yes. We provide OEM/ODM services for custom capacity, layout, power options, and regeneration methods.

Why Choose Our Desiccant Air Dryers for Compressed Air?

🌐 Global Standards: CE/ASME certified, globally accepted

⚙️ Customization: Wide range of sizes and options

📦 Fast Delivery: In-stock models and fast production for custom orders

🧠 Smart Controls: Optional dew point sensors and purge control systems

🔧 Reliable After-Sales Support: Lifetime technical assistance and spare parts

Get a Quote Today

Looking for reliable and efficient desiccant air dryers for compressed air? Contact our team now for a quote, technical consultation, or a free application analysis. Let’s help you keep your air dry and your operations running smoothly.

Related products:

2, Minimum regeneration gas consumption

3. Long service life of adsorbent

4. Easy maintenance

5. High safety

6. High reliability

7.Adjustable regeneration gas consumption

8. Optional dew point monitoring and control system

2. Resists chemical corrosion and extends service life

3. Special sealing technology prevents flammable gases or dust from entering theinterior of the machine

4. Regeneration gas consumption can be adjusted, with energy saving and dewpoint adjustment function

2, Customized high-performance adsorbent, 20% filling margin;

3. Branded high-pressure blower, high-performance pneumatic valve, high-efficiency cooler designed by HTFS software, reliable performance and long life;

4. 304 stainless steel control gas pipeline, specially designed diverter, highadsorbent utilization rate and low gas pressure loss;