🔧 Nitrogen Generators Specs: Everything You Need to Know Before You Buy

Whether you’re in food packaging, pharmaceuticals, or laser cutting, nitrogen plays a critical role in improving process efficiency, safety, and product quality. But choosing the right nitrogen generator starts with understanding one thing: nitrogen generators specs.

This article will walk you through the most essential nitrogen generators specs, helping you make an informed decision for your business.

📘What Are Nitrogen Generators?

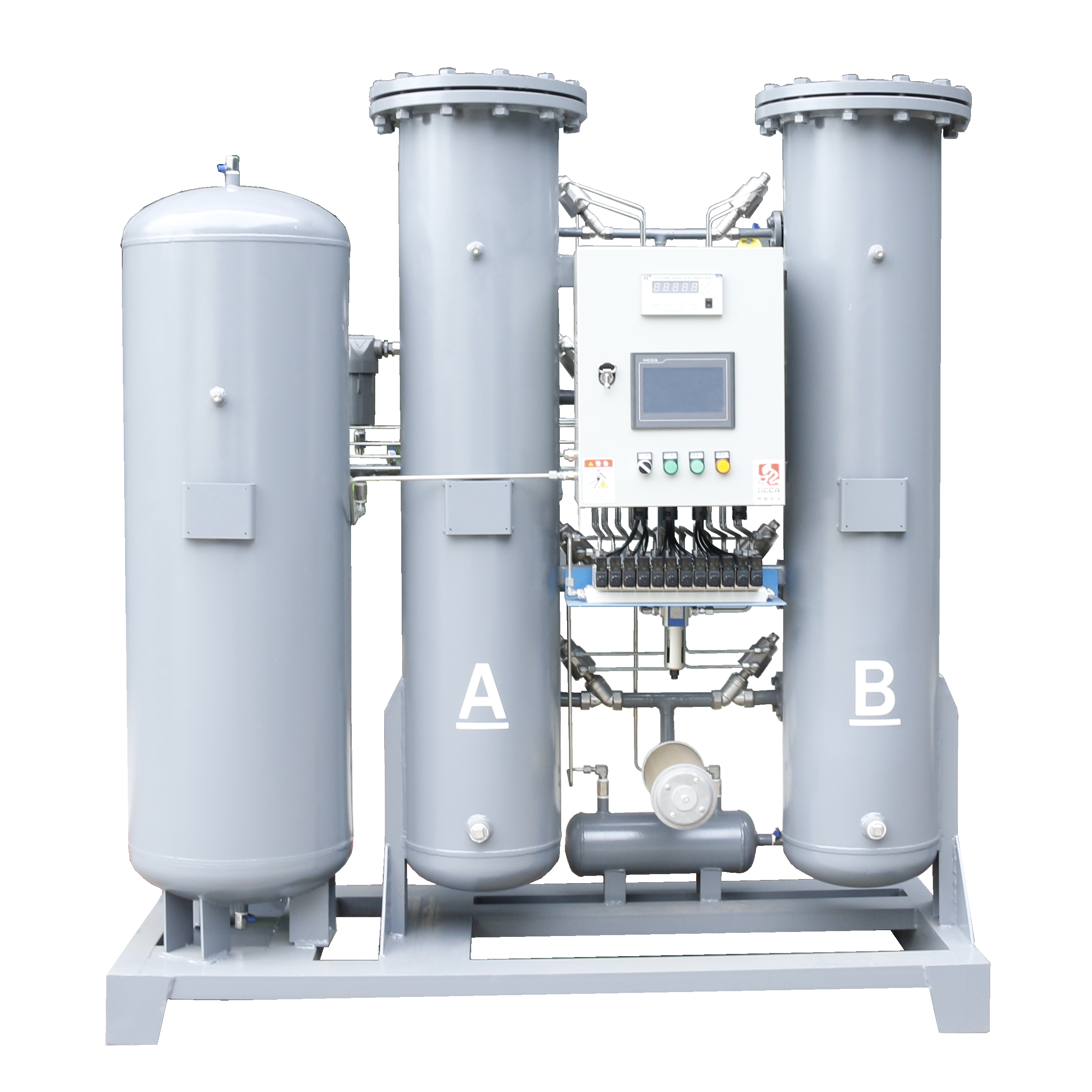

A nitrogen generator is an on-site gas generation system that separates nitrogen from the atmosphere using Pressure Swing Adsorption (PSA) or Membrane technology. These generators provide a continuous and cost-effective supply of high-purity nitrogen for a wide range of applications.

Before purchasing one, you must evaluate the nitrogen generators specs to ensure compatibility with your industrial requirements.

📐Key Nitrogen Generators Specs You Must Consider

Here are the most important nitrogen generators specs you should focus on when evaluating options:

| Spec Type | Description |

|---|---|

| Flow Rate (Nm³/h or SCFM) | How much nitrogen the generator produces per hour |

| Purity Level (%) | The concentration of nitrogen gas (usually 95%–99.999%) |

| Operating Pressure (Bar/PSI) | The pressure at which nitrogen is delivered |

| Dew Point | The dryness of the nitrogen output, typically −40°C or lower |

| Air Consumption Ratio | How much compressed air is required to produce nitrogen |

| Power Consumption (kW) | Energy used by the generator |

| Technology Type | PSA or Membrane-based generation |

| Footprint/Dimensions | Physical size of the machine |

| Noise Level (dB) | Operational noise, important for indoor environments |

| Control Interface | PLC, touchscreen, or manual operation |

Each of these nitrogen generators specs plays a crucial role in performance, efficiency, and application compatibility.

💼Typical Applications Requiring Precise Nitrogen Generators Specs

Choosing the correct nitrogen generators specs ensures your system delivers consistent and efficient nitrogen production in industries such as:

Food & Beverage (Modified Atmosphere Packaging)

Laser Cutting & CNC

Pharmaceuticals & Laboratories

Electronics Manufacturing

Petrochemical Plants

Bottling & Beverage Dispensing

Automotive Industry (Tire Inflation)

📊Sample Nitrogen Generators Specs from Lingyu

Below are the specifications for some of Lingyu’s most popular nitrogen generators:

| Model | Flow Rate (Nm³/h) | Purity (%) | Pressure (Bar) | Technology | Power (kW) |

|---|---|---|---|---|---|

| LYN2-10 | 10 | 99.999 | 7 | PSA | 0.5 |

| LYN2-30 | 30 | 99.99 | 8 | PSA | 1.1 |

| LYN2-50 | 50 | 99.9 | 7.5 | PSA | 1.5 |

| LYN2-M20 | 20 | 99 | 6 | Membrane | 0.3 |

We also offer custom nitrogen generators specs for clients with unique purity, pressure, or flow demands.

💡How to Choose the Right Nitrogen Generators Specs for Your Needs

Not all nitrogen generators are created equal. The “best” nitrogen generators specs depend entirely on your application.

Step-by-step evaluation guide:

Determine Required Flow Rate

Know your peak nitrogen demand in Nm³/h or SCFM.Choose Your Required Purity

95%–98% for tire inflation or fire prevention

99.9%–99.999% for pharmaceuticals or electronics

Check Compatible Pressure Level

Make sure the generator output pressure matches your system.Consider Ambient Conditions

Temperature and humidity can affect performance.Match Air Supply Capacity

Ensure your air compressor meets the air-to-nitrogen ratio required.Space & Utility Requirements

Evaluate available installation space and electrical supply.

By analyzing these criteria, you can match the nitrogen generators specs to your exact use case.

🛠️Why Nitrogen Generators Specs Matter for Operational Efficiency

Getting the specs right affects:

✅ Product Quality

⚙️ Equipment Life

💰 Energy Costs

🔒 Safety and Compliance

⏱ Downtime Reduction

Under-spec’d systems lead to poor gas quality and interruptions. Over-spec’d systems waste energy and capital.

💬Marketing Copy — Discover the Perfect Nitrogen Generator with Lingyu

Optimize Your Workflow with Precision-Tuned Nitrogen Generators Specs

At Lingyu, we understand that every business has unique gas generation needs. That’s why we offer a full range of PSA and membrane nitrogen generators with customizable specs. Whether you need ultra-high purity nitrogen for laser cutting or low-purity supply for fire prevention, we have a model that matches your requirements.

🚀 Flow rates from 5 Nm³/h to 1000+ Nm³/h

🎯 Purity levels up to 99.999%

⚡ Energy-efficient performance with intelligent PLC control💬 Talk to our experts today for a free consultation and unlock the best-fit nitrogen generator specs for your plant.

🤔FAQ — Nitrogen Generators Specs

What is the ideal nitrogen purity for food packaging?

For MAP (Modified Atmosphere Packaging), you typically need 99% to 99.5% nitrogen purity.

How much compressed air is needed to produce nitrogen?

This depends on your generator type and flow. On average, PSA generators require 6–8 Nm³ of air for every 1 Nm³ of nitrogen.

Can I get nitrogen at 99.999% purity?

Yes. Lingyu’s PSA models offer ultra-high purity options up to 99.999%, suitable for electronics and medical applications.

What’s the difference between PSA and membrane specs?

PSA offers higher purity and pressure but has higher energy usage. Membrane systems are compact and ideal for lower purity needs (95%–99%).

Do nitrogen generator specs vary by region?

Yes. Factors like ambient temperature, humidity, and electrical standards can affect the specs required in different environments.

✅ Conclusion: Start with the Right Specs, End with the Right Results

Selecting the correct nitrogen generators specs is the first step toward achieving optimal performance, safety, and cost-efficiency in your operations. Whether you’re scaling your production line or upgrading your gas supply system, knowing your specs ensures your investment pays off.

🔎 Need help interpreting technical specs?

📞 Contact Lingyu’s technical team today—we’ll help you configure the perfect nitrogen generator with tailored specifications for your operation.

Related products:

Nitrogen generator with 99.99% purity—reliable, efficient, and built for demanding industrial applications.