As industries demand higher purity nitrogen with lower operating costs, the Pressure Swing Adsorption nitrogen generator has become one of the most widely adopted solutions. Instead of depending on bulk nitrogen deliveries or expensive cylinder rentals, businesses can now produce nitrogen on-site, on-demand, and with excellent efficiency.

So what exactly is a PSA nitrogen generator, how does it work, and why has it become essential across manufacturing, food processing, electronics, and more? This article breaks it down in a clear, high-originality overview.

What Is a Pressure Swing Adsorption (PSA) Nitrogen Generator?

A PSA nitrogen generator is an on-site gas generation system that extracts nitrogen directly from the surrounding air. It uses a specialized adsorption process to separate oxygen and other trace gases, delivering a continuous nitrogen stream with purity levels up to 99.999%, depending on the design.

The technology is built around Carbon Molecular Sieve (CMS) and pressure cycling, making high-purity nitrogen production both reliable and energy-efficient.

How PSA Technology Works

PSA generators operate using a simple but highly effective principle: gases can be separated by using materials that adsorb specific molecules under pressure.

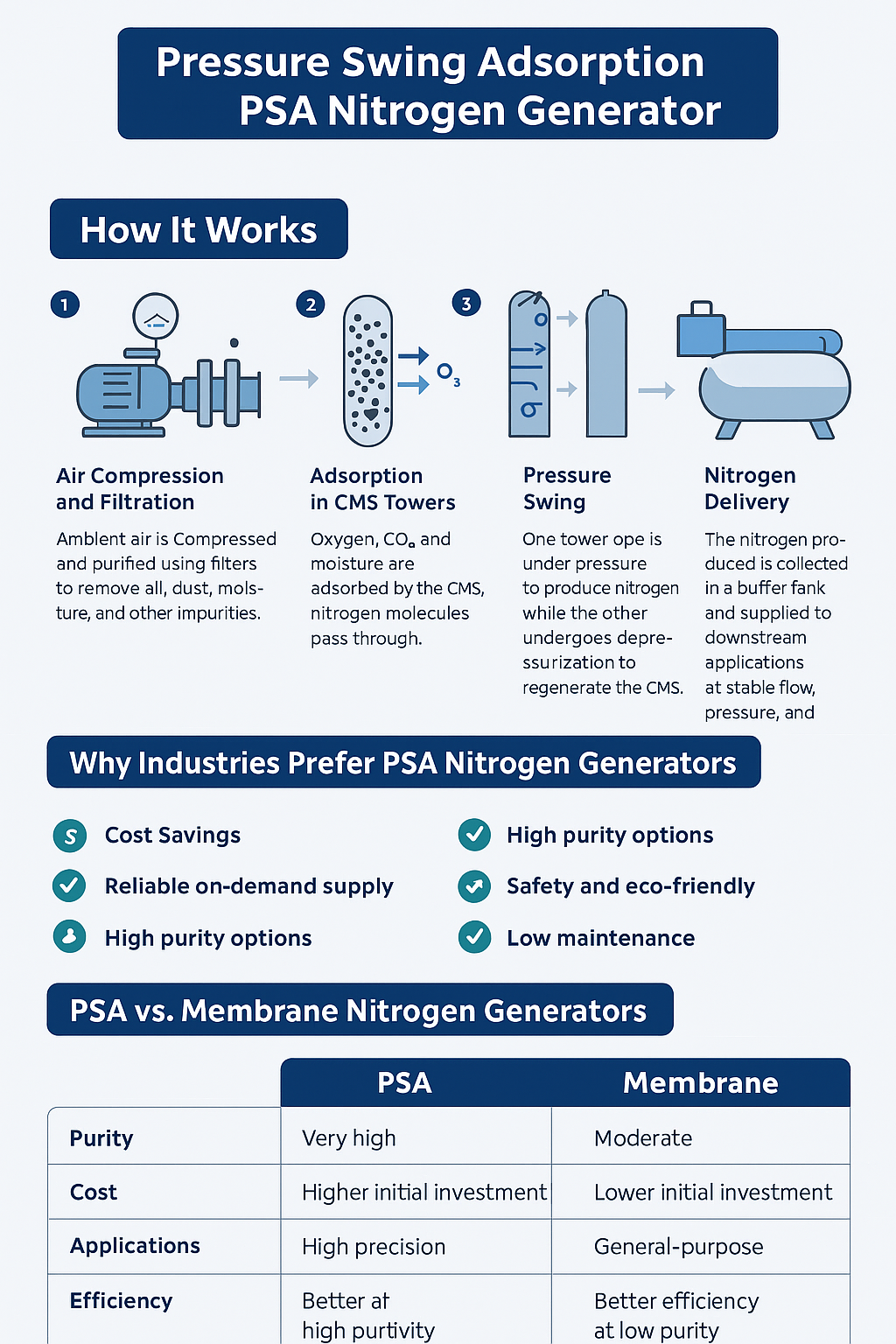

Here’s how the process works step-by-step:

1. Air Compression and Filtration

Ambient air is compressed and purified using filters to remove oil, dust, moisture, and other impurities.

2. Adsorption in CMS Towers

The cleaned air enters two CMS-filled adsorption vessels.

Oxygen, CO₂, and moisture are adsorbed by the CMS

Nitrogen molecules pass through, thanks to their larger molecular size and lower adsorption tendency

3. Pressure Swing

One tower operates under pressure to produce nitrogen while the other undergoes depressurization to regenerate the CMS.

This cycling—pressurize one vessel, depressurize the other—ensures continuous nitrogen output.

4. Nitrogen Delivery

The nitrogen produced is collected in a buffer tank and supplied to downstream applications at stable flow, pressure, and purity.

Why Industries Prefer PSA Nitrogen Generators

Compared with cryogenic nitrogen or cylinder deliveries, PSA generators offer several advantages:

✔ Significant Cost Savings

Producing nitrogen on-site eliminates recurring costs for cylinders, refills, delivery fees, and rental charges.

✔ Reliable On-Demand Supply

No more waiting for deliveries or running out of gas during critical operations.

✔ High Purity Options

PSA units can achieve nitrogen purities ranging from 95% to 99.999%, suitable for even the most sensitive applications.

✔ Safe and Eco-Friendly

Since nitrogen is produced from ambient air, it reduces transportation emissions and eliminates the hazards of storing high-pressure cylinders.

✔ Low Maintenance

PSA systems have few moving parts, resulting in long service life and minimal downtime.

Where PSA Nitrogen Generators Are Used

PSA nitrogen technology is used across a wide range of industries due to its safety, cost-effectiveness, and purity control:

1. Food & Beverage

Modified atmosphere packaging (MAP)

Food storage and preservation

Preventing oxidation and spoilage

2. Electronics & Semiconductors

Inert atmospheres for PCB manufacturing

Soldering and wave-soldering processes

3. Chemical & Pharmaceutical

Blanketing and purging

Inert gas systems

Controlled atmospheres for production

4. Metal Processing

Laser cutting

Heat treatment

Powder metallurgy

5. Oil, Gas & Petrochemicals

Pipeline purging

Tank blanketing

Pressure maintenance

With customizable flow rates and purity levels, PSA nitrogen generators fit both small production facilities and large industrial plants.

PSA vs. Membrane Nitrogen Generators: What’s the Difference?

While both technologies generate nitrogen from compressed air, they serve different needs:

| Feature | PSA | Membrane |

|---|---|---|

| Purity | Very high (up to 99.999%) | Moderate (up to ~99%) |

| Cost | Higher initial investment | Lower initial investment |

| Applications | High-precision | General-purpose |

| Efficiency | Better at high purity | Better at low purity |

If your application requires high-purity nitrogen, PSA is typically the best choice.

Is a PSA Nitrogen Generator Right for Your Business?

A pressure swing adsorption nitrogen generator is ideal if you need:

Continuous nitrogen supply

High purity levels

Lower long-term operating costs

A safer and more reliable alternative to cylinder storage

From optimizing production to enhancing workplace safety, PSA nitrogen generators provide a long-term, sustainable solution for nitrogen supply.