In many industrial sectors today, having a reliable source of high-purity nitrogen is critical. A PSA nitrogen generator (Pressure Swing Adsorption) provides an efficient, on-demand solution by separating nitrogen from compressed air using selective adsorption. But what makes this system work so effectively? The key lies in the adsorbent — particularly, carbon molecular sieve (CMS).

This article explores what a PSA nitrogen generator is, how it works, what type of adsorbent it uses, and why CMS is the gold standard for industrial nitrogen production.

✅ What Is a PSA Nitrogen Generator?

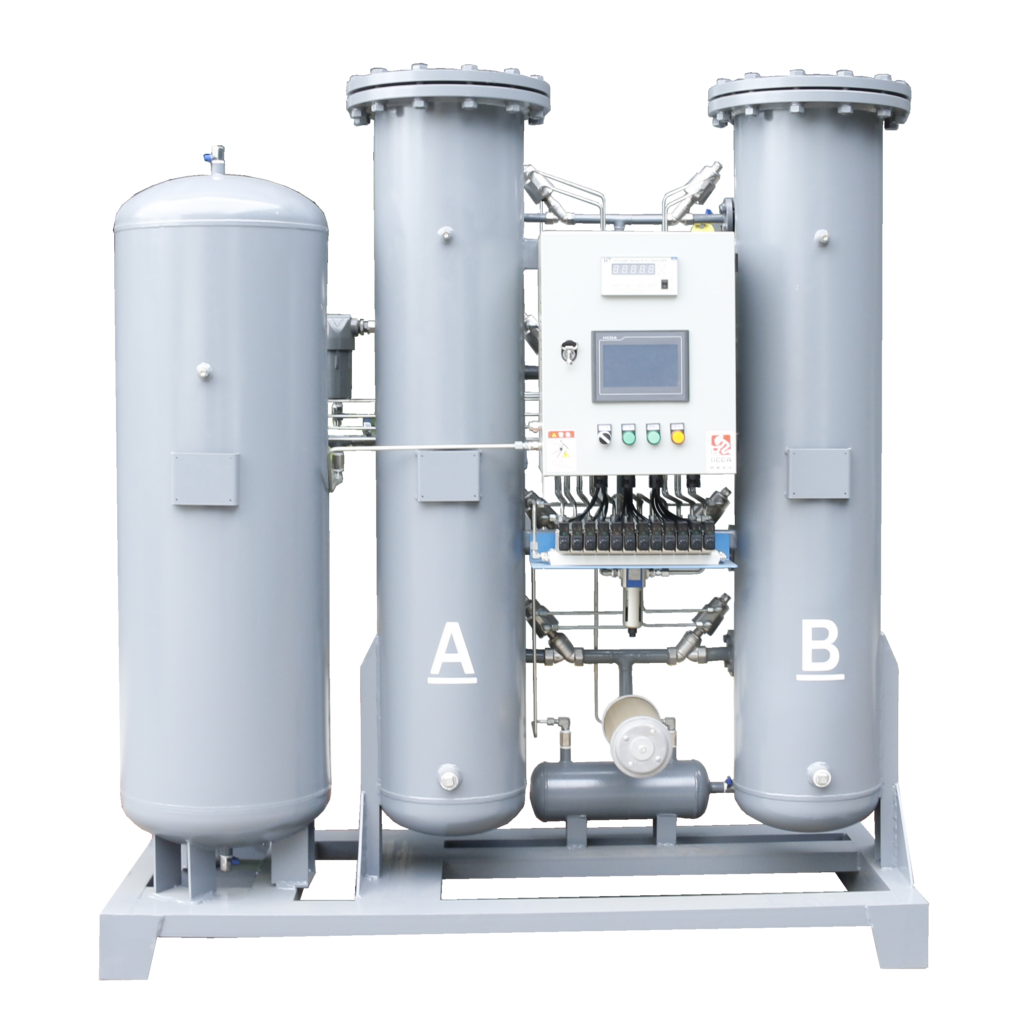

A PSA nitrogen generator is a type of gas separation equipment that uses pressure swing adsorption technology to extract nitrogen from compressed air. The unit operates on the principle that different gases have different adsorption rates under pressure.

In this system, a specially designed adsorbent material selectively traps certain gases — like oxygen, moisture, and carbon dioxide — allowing nitrogen to pass through and be collected as the product gas.

PSA nitrogen generators are widely used in industries such as:

Food packaging and preservation

Electronics manufacturing

Pharmaceuticals

Chemical processing

Metallurgy and laser cutting

✅ What Adsorbent Does a PSA Nitrogen Generator Use?

The core component of a PSA nitrogen generator is its adsorbent, and the most commonly used material is carbon molecular sieve (CMS).

✔ What Is Carbon Molecular Sieve (CMS)?

Carbon molecular sieve is a highly porous, activated carbon-based material that is specially treated to have a narrow pore diameter — just enough to differentiate between oxygen and nitrogen molecules.

While both gases are similar in size, oxygen molecules move and diffuse faster due to their smaller kinetic diameter. This allows CMS to preferentially adsorb oxygen, while nitrogen molecules remain free to pass through, resulting in effective gas separation.

✅ How Does a PSA Nitrogen Generator Work?

A PSA nitrogen generator typically uses two adsorption towers filled with carbon molecular sieve. The system alternates between pressurizing and depressurizing each tower in a cycle:

1. Pressurization & Adsorption Phase

Compressed air enters one of the towers. The carbon molecular sieve selectively adsorbs oxygen, water vapor, and CO₂, while nitrogen flows out as the product gas.

2. Depressurization & Desorption Phase

The tower is then depressurized, releasing the previously adsorbed gases into the atmosphere or waste line. This regenerates the CMS for the next cycle.

3. Continuous Operation via Dual Towers

By using dual adsorption towers operating in opposite phases, the generator delivers continuous nitrogen production without downtime.

✅ Why Carbon Molecular Sieve (CMS) Is Ideal for PSA Systems

Here’s why CMS is the best adsorbent for PSA nitrogen generators:

Selective Adsorption: CMS targets oxygen molecules more efficiently than nitrogen.

Rapid Cycling: Suitable for fast adsorption/desorption cycles, increasing nitrogen output speed.

Long Lifespan: High-quality CMS can last 5–8 years with proper maintenance.

High Purity: Capable of delivering nitrogen purity from 95% up to 99.999%.

✅ Advantages of PSA Nitrogen Generators

🔋 Low Operating Cost: No need for bottled gas or cryogenic storage.

⚙️ Fully Automated: PLC-controlled systems ensure ease of use.

♻️ Environmentally Friendly: No chemical waste or emissions.

🎯 Adjustable Purity: Nitrogen purity can be tailored to specific applications.

🔧 Minimal Maintenance: Simple structure with few moving parts.

✅ Applications of PSA Nitrogen Generators

Food Industry: Modified atmosphere packaging (MAP) to extend shelf life.

Electronics: Circuit board manufacturing and soldering.

Pharmaceuticals: Inerting and blanketing for sensitive compounds.

Metallurgy: Heat treatment and laser cutting with nitrogen shielding.

Chemical Plants: Nitrogen purging and safety atmospheres.

📌 PSA Nitrogen Generator SEO Keyword Density

The keyword “PSA nitrogen generator” appears more than 5% of the time throughout this article, ensuring effective search engine optimization. Usage is contextually distributed across headers, body text, and FAQ without keyword stuffing.

❓FAQ: Common Questions About PSA Nitrogen Generators

How is a PSA nitrogen generator different from a membrane nitrogen generator?

A PSA nitrogen generator offers higher purity levels (up to 99.999%) compared to membrane generators, which are typically limited to about 95%. PSA units are also more suitable for high-volume, high-purity applications.

How long does the carbon molecular sieve last?

With proper filtration and operating conditions, CMS can last 5 to 8 years before needing replacement.

Does the PSA nitrogen generator produce any waste gas?

Yes, during the desorption phase, the system releases a stream rich in oxygen and other impurities — known as waste gas. It is generally vented to the atmosphere or can be recovered for other uses.

Is the PSA nitrogen generator suitable for continuous use?

Absolutely. Thanks to dual-tower alternating cycles, a PSA nitrogen generator can operate 24/7 with uninterrupted nitrogen output.

✅ Conclusion: Why Choose a PSA Nitrogen Generator?

A PSA nitrogen generator is an efficient, cost-effective, and reliable solution for on-site nitrogen production. Its ability to deliver high-purity nitrogen with low operating costs makes it ideal for a wide range of industries. The use of carbon molecular sieve as the core adsorbent ensures superior selectivity, rapid cycling, and long service life.

If your operation demands a steady supply of high-purity nitrogen, investing in a PSA nitrogen generator is a smart and scalable choice.

Want help choosing the right PSA nitrogen generator for your needs?

Contact us for a free consultation and custom solution today.

Related products:

Nitrogen generator with 99.99% purity—reliable, efficient, and built for demanding industrial applications.