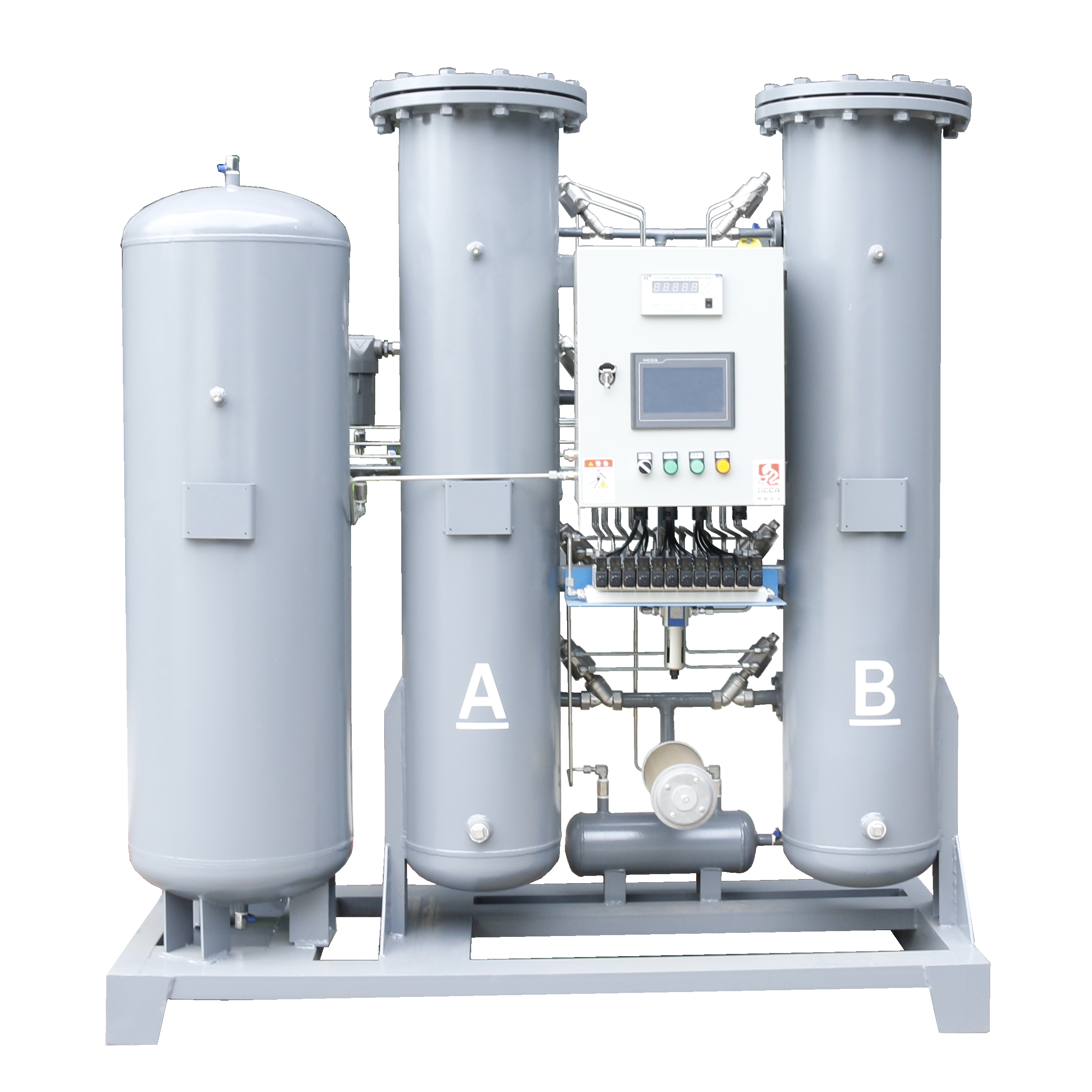

A PSA Nitrogen Generator (Pressure Swing Adsorption Nitrogen Generator) is a widely used industrial nitrogen production system that separates nitrogen from oxygen using specialized adsorbent materials under controlled pressure conditions. Selecting the right PSA Nitrogen Generator is crucial for ensuring consistent gas quality, operational efficiency, and long-term cost savings.

In this guide, we will break down the key factors to consider when choosing the best PSA Nitrogen Generator for your needs.

1. Nitrogen Purity Requirements

Different industries require different nitrogen purity levels. For example:

Food and beverage production often requires nitrogen purity above 99.9% to prevent oxidation.

Medical applications may demand ultra-high purity to meet strict safety standards.

Electronics manufacturing often needs nitrogen with minimal oxygen content to avoid defects.

When selecting a PSA Nitrogen Generator, identify your target nitrogen purity and choose a system that can consistently deliver it.

2. Nitrogen Flow Rate

Flow rate is one of the most critical parameters in PSA Nitrogen Generator selection. Consider:

Your maximum nitrogen consumption during peak production.

Potential fluctuations in demand.

A safety margin to ensure stable supply.

Choosing the correct generator size avoids bottlenecks and ensures operational continuity.

3. Operating Pressure and Temperature

Some processes require specific nitrogen delivery pressures and temperatures. A PSA Nitrogen Generator should be compatible with:

The pressure range required by your production line.

The ambient temperature conditions of your facility.

This ensures seamless integration without costly modifications.

4. Energy Consumption

Energy efficiency directly impacts the operating cost of a PSA Nitrogen Generator. Look for:

Low specific energy consumption (kWh per Nm³ of nitrogen).

Advanced control systems for optimized performance.

Waste heat recovery or air recycling options for better sustainability.

5. Reliability and Maintenance

A reliable PSA Nitrogen Generator minimizes downtime and maintenance costs. Before purchasing, evaluate:

The manufacturer’s reputation and technical support.

Availability of spare parts.

Ease of maintenance and monitoring.

6. Compliance and Certification

Ensure your PSA Nitrogen Generator complies with relevant industry standards and regulations. Certifications such as ISO, CE, or FDA compliance can be crucial for certain industries.

Conclusion

Selecting the right PSA Nitrogen Generator involves balancing nitrogen purity, flow rate, operating pressure, energy efficiency, reliability, and certification requirements. By working closely with an experienced nitrogen equipment supplier, you can ensure your system delivers both performance and long-term economic benefits.

FAQ: PSA Nitrogen Generator Selection

What is the main advantage of a PSA Nitrogen Generator over liquid nitrogen supply?

A PSA Nitrogen Generator allows on-site nitrogen production, eliminating the need for costly and logistically complex nitrogen deliveries.

How long does a PSA Nitrogen Generator last?

With proper maintenance, most PSA Nitrogen Generators can operate efficiently for 10–15 years or more.

Can I upgrade my PSA Nitrogen Generator later?

Yes, many systems are modular and can be expanded to meet future nitrogen demands.

How often does a PSA Nitrogen Generator require maintenance?

Typically, basic maintenance is performed every 6–12 months, depending on usage and environmental conditions.

Related products:

Nitrogen generator with 99.99% purity—reliable, efficient, and built for demanding industrial applications.