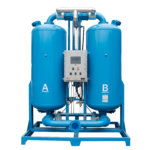

The regenerative desiccant air dryer is an advanced solution for removing moisture from compressed air systems. By utilizing twin towers filled with high-performance desiccant materials, this dryer ensures a continuous supply of ultra-dry air with dew points reaching as low as -70°C. Whether you’re operating in demanding industries like electronics, pharmaceuticals, or petrochemicals, a regenerative desiccant air dryer offers the reliability and efficiency your system needs.

Our regenerative desiccant air dryer is engineered for high-performance, energy-saving operation, and long service life, making it ideal for facilities that require consistent dry air to maintain product quality and protect critical equipment.

Key Features of Regenerative Desiccant Air Dryer

✅ Low Dew Point Capability

Achieves dew points of -20°C to -70°C, suitable for moisture-sensitive applications.✅ Dual Tower Design

Continuous operation via alternating adsorption and regeneration cycles.✅ Energy-Efficient Regeneration

Heatless, heated purge, and blower purge options available to reduce energy consumption.✅ Advanced Control System

Equipped with a PLC control panel and LED display for easy monitoring and automatic switching.✅ High-Quality Desiccant

Filled with activated alumina or molecular sieve with strong moisture adsorption and long service life.✅ Durable Construction

Corrosion-resistant powder-coated frame, heavy-duty valves, and stainless steel internals.

Operating Conditions & Technical Requirements

| Parameter | Value |

|---|---|

| Working Pressure | 4–10 bar (58–145 psi) |

| Inlet Air Temperature | ≤50°C (122°F) |

| Ambient Temperature | 5–45°C (41–113°F) |

| Dew Point | -20°C to -70°C |

| Power Supply | 220V/1Ph or 380V/3Ph, 50/60Hz |

| Regeneration Type | Heatless / Heated / Blower purge |

The regenerative desiccant air dryer is optimized to perform in varied environmental and industrial conditions while maintaining stable output and low maintenance.

Technical Specifications (Sample Table)

| Model | Flow Rate (SCFM) | Desiccant (kg) | Inlet/Outlet | Power (W) | Dew Point (°C) |

|---|---|---|---|---|---|

| LY-50 | 50 | 25 | DN20 | 30 | -40 |

| LY-100 | 100 | 50 | DN25 | 50 | -40 |

| LY-200 | 200 | 90 | DN32 | 80 | -40 |

| LY-500 | 500 | 200 | DN50 | 150 | -40/-70 |

| LY-1000 | 1000 | 400 | DN80 | 300 | -40/-70 |

Custom models available up to 5000 SCFM. Contact us for detailed sizing and engineering support.

Applications of Regenerative Desiccant Air Dryer

The regenerative desiccant air dryer is widely used in sectors that require extremely dry compressed air:

🏭 Manufacturing Plants – Ensures reliable operation of pneumatic tools and actuators

💊 Pharmaceutical Industry – Maintains sterile and moisture-free conditions

🛢️ Oil & Gas – Prevents hydrate formation and corrosion in pipelines

📱 Electronics & Semiconductors – Prevents defects and moisture-related failures

🚗 Automotive Coating & Painting – Ensures smooth and bubble-free paint application

🧪 Laboratories & Testing Facilities – Maintains consistent conditions for precision instruments

Frequently Asked Questions (FAQ)

Q1: What is a regenerative desiccant air dryer?

A: It’s a twin-tower system that uses desiccant material to remove water vapor from compressed air, automatically regenerating one tower while the other operates.

Q2: What dew point can this dryer achieve?

A: A regenerative desiccant air dryer can achieve dew points as low as -70°C, depending on model and operating conditions.

Q3: What is the difference between heatless and heated types?

A: Heatless models use a portion of dry air for regeneration. Heated models use electric or blower heat, reducing purge loss and improving energy efficiency.

Q4: How often does the desiccant need to be replaced?

A: Typically every 1–2 years under normal conditions. Proper pre-filtration can extend desiccant life.

Q5: Can I use this dryer in high-humidity environments?

A: Yes. The regenerative desiccant air dryer is designed to handle high inlet moisture loads and still deliver ultra-dry air.

Why Choose Our Regenerative Desiccant Air Dryer?

🌍 Exported to over 60 countries worldwide

🧰 Custom solutions available for any industry

🛠️ Factory-tested, ISO-certified, and CE-marked

💡 Expert engineering support for sizing and integration

📦 OEM & ODM branding support

Call to Action

Upgrade your compressed air system with our high-performance regenerative desiccant air dryer. Contact our team today for pricing, technical support, or to request a custom quote tailored to your needs.

Related products:

2, Minimum regeneration gas consumption

3. Long service life of adsorbent

4. Easy maintenance

5. High safety

6. High reliability

7.Adjustable regeneration gas consumption

8. Optional dew point monitoring and control system

2. Resists chemical corrosion and extends service life

3. Special sealing technology prevents flammable gases or dust from entering theinterior of the machine

4. Regeneration gas consumption can be adjusted, with energy saving and dewpoint adjustment function

2, Customized high-performance adsorbent, 20% filling margin;

3. Branded high-pressure blower, high-performance pneumatic valve, high-efficiency cooler designed by HTFS software, reliable performance and long life;

4. 304 stainless steel control gas pipeline, specially designed diverter, highadsorbent utilization rate and low gas pressure loss;