Why PSA Nitrogen Generator Purity May Fail: Causes and Solutions

PSA nitrogen generator systems are widely used across many industries where a reliable supply of high-purity nitrogen is critical. From electronics and pharmaceuticals to food packaging and chemical processing, a PSA nitrogen generator plays a vital role in maintaining product quality and safety. However, in certain cases, the nitrogen purity levels may fall short of expectations, leading to costly issues.

In this article, we explore the main causes behind nitrogen purity failures in PSA nitrogen generator systems and offer solutions to keep your operation running at optimal levels.

What Is a PSA Nitrogen Generator?

A PSA nitrogen generator (Pressure Swing Adsorption nitrogen generator) utilizes a process where compressed air is passed through a bed of carbon molecular sieve (CMS), which adsorbs oxygen while allowing nitrogen to pass through. This physical separation method enables the delivery of nitrogen with purities typically ranging from 95% to 99.999%.

Maintaining this purity, however, requires that the system runs under specific operating conditions. Let’s explore what could go wrong.

1. Carbon Molecular Sieve Degradation or Failure

The core of the PSA nitrogen generator is the carbon molecular sieve (CMS). Over time, the CMS can degrade due to:

Overuse or extended operational life

Exposure to contaminants like oil vapors and moisture

Improper regeneration cycles

Once the CMS loses its ability to selectively adsorb oxygen, the system can no longer effectively separate gases, leading to a drop in nitrogen purity. Routine CMS performance checks and timely replacement are essential for maintaining gas separation efficiency.

2. Contaminated Feed Air

The quality of compressed air fed into the PSA nitrogen generator directly affects its performance. If the feed air contains:

High levels of water vapor

Oil mist

Dust or organic vapors

…these contaminants can clog the CMS, reducing its adsorption efficiency. This not only lowers the nitrogen purity but can also cause long-term damage to the adsorbent material.

Solution:

Install high-quality pre-filtration systems like coalescing filters and refrigerated or desiccant air dryers. Regular maintenance of the filtration system is critical to ensure clean, dry air enters the PSA nitrogen generator.

3. Equipment Leaks and Valve Failures

The PSA nitrogen generator relies on precise pressure control and valve switching to maintain the adsorption and regeneration cycles. Common mechanical issues that lead to purity failure include:

Valve malfunction

Air leakage from pipelines or vessels

Incorrect cycle timing

If any of these mechanical issues arise, the timing of adsorption and desorption can be disrupted, leading to inefficient gas separation.

Solution:

Regular inspection and calibration of valves, pressure sensors, and seals is necessary. Any signs of leaks or pressure drops should be addressed immediately.

4. Incorrect Operating Parameters

Operating the PSA nitrogen generator outside its specified parameters can also lead to lower nitrogen purity. Factors such as:

Incorrect pressure settings

High flow demand beyond rated capacity

Improper cycle timing adjustments

…can overwhelm the system’s ability to separate oxygen from nitrogen.

Solution:

Always follow manufacturer-recommended settings for pressure, flow rate, and timing. Employ flow meters and oxygen analyzers to monitor real-time performance.

5. Operator Error or Lack of Training

Even with the most advanced PSA nitrogen generator, improper operation by untrained personnel can result in significant performance degradation. Common mistakes include:

Skipping maintenance routines

Failing to monitor purity levels

Overlooking system alerts or diagnostics

Solution:

Provide comprehensive training to all operators on system usage, maintenance schedules, and emergency procedures.

Conclusion

To ensure that your PSA nitrogen generator consistently delivers high-purity nitrogen, it’s essential to:

Monitor the condition of the carbon molecular sieve

Maintain clean and dry inlet air

Conduct regular system checks

Operate the unit within specified parameters

Train operators on best practices

By proactively addressing these issues, you can maintain system efficiency, reduce downtime, and ensure a steady supply of high-purity nitrogen.

PSA Nitrogen Generator Purity Issues

How often should I replace the carbon molecular sieve in a PSA nitrogen generator?

Typically every 3–5 years, depending on operating conditions and air quality. Regular performance tests can help you decide.

Can I use any type of compressed air with a PSA nitrogen generator?

No. The compressed air must be clean and dry, free of oil and water contaminants.

What is the acceptable nitrogen purity for industrial use?

Most industrial applications require 95–99.99% purity. The exact requirement depends on the use case.

What is the impact of high flow demand on nitrogen purity?

Exceeding the designed flow capacity can shorten adsorption time and reduce nitrogen purity.

How can I detect air leaks in my system?

Use ultrasonic leak detectors or conduct a pressure drop test during shutdown periods.

Additional Tips

Use an oxygen analyzer to continuously monitor nitrogen purity.

Schedule annual audits by certified technicians.

Always keep a logbook for system performance and maintenance history.

Related products:

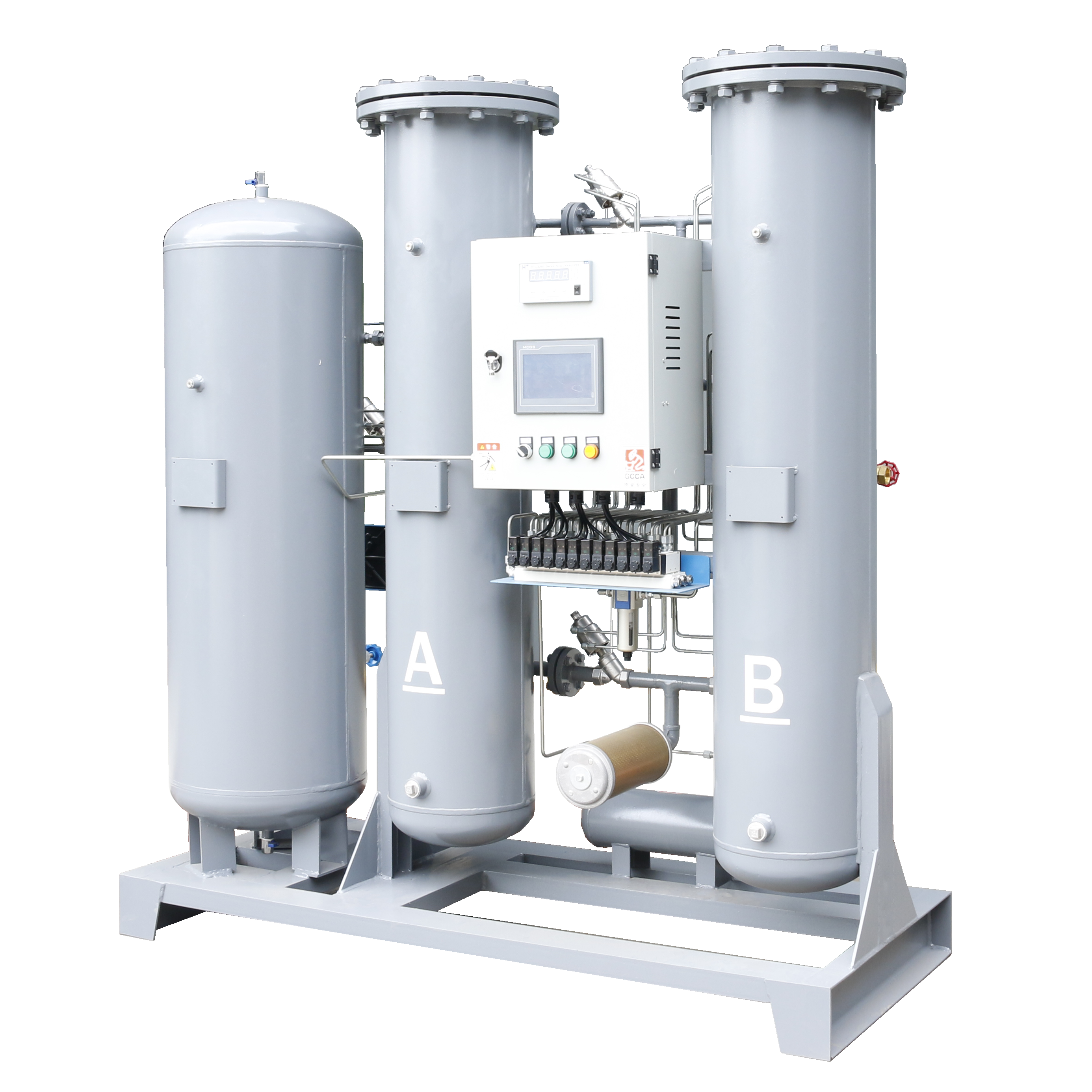

Nitrogen generator with 99.99% purity—reliable, efficient, and built for demanding industrial applications.