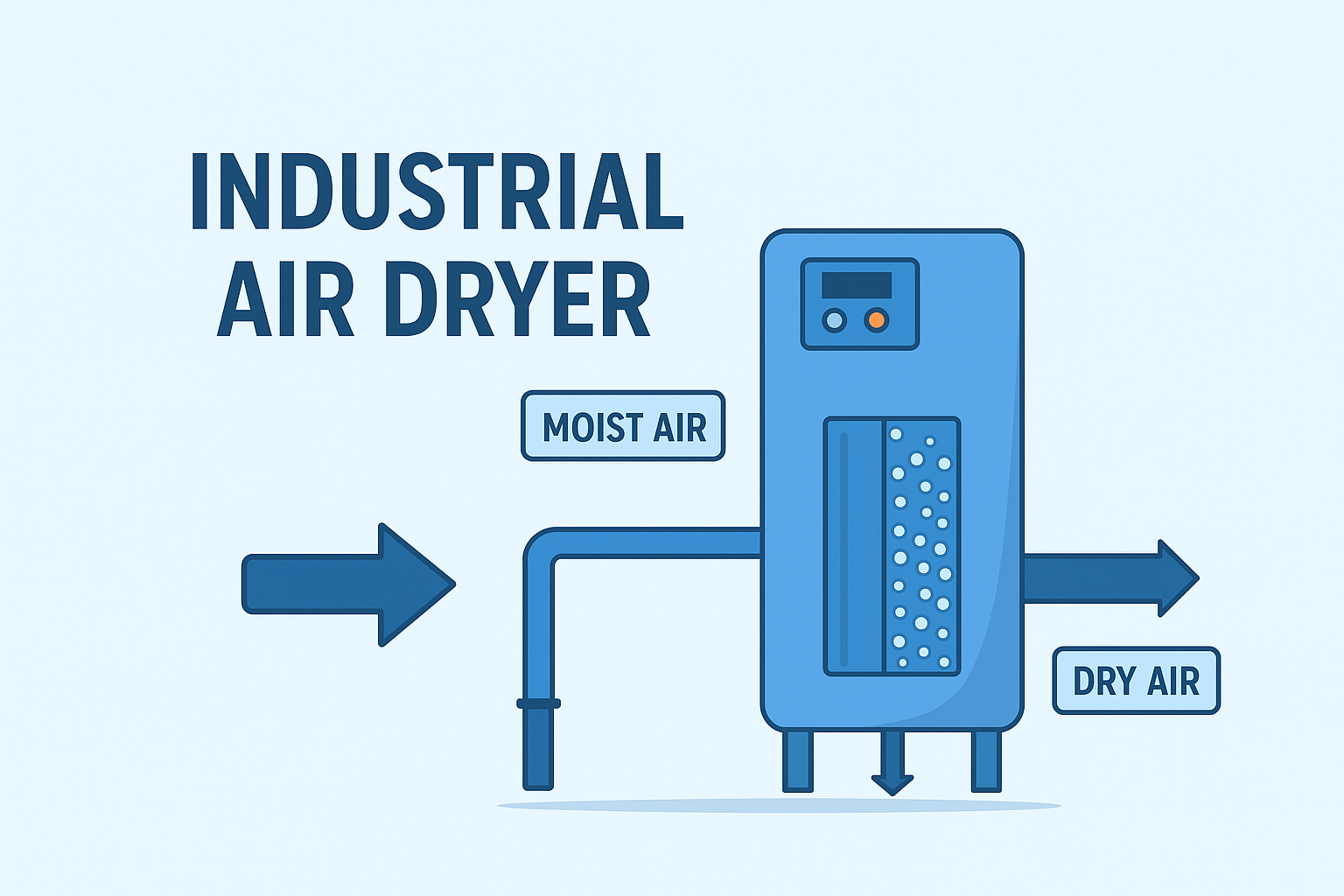

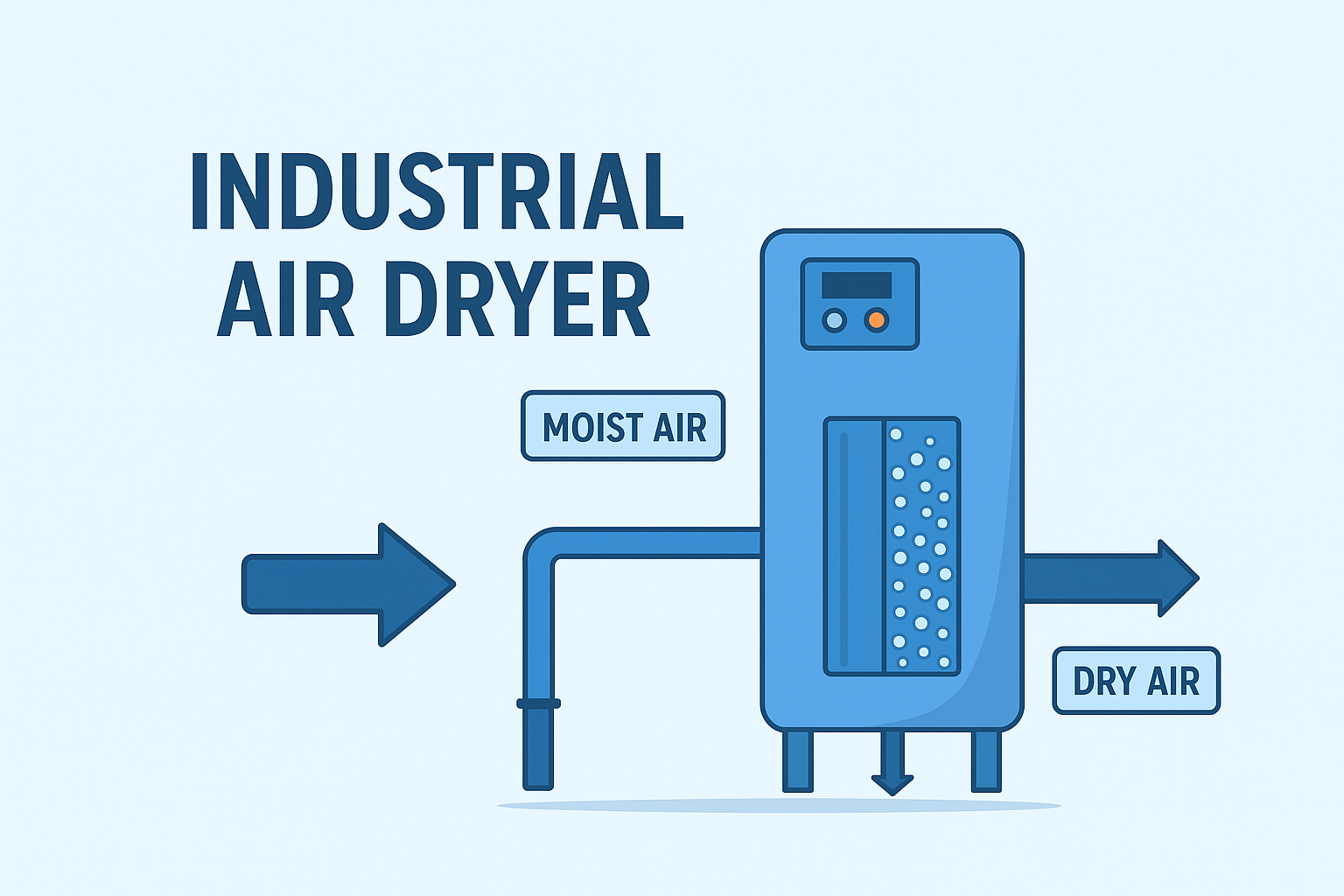

Industrial Air Dryer: What It Is, How It Works, and Where It’s Used

Moisture is one of the biggest challenges in industrial compressed air systems. When air is compressed, water vapor condenses into liquid, which can damage machinery,

Moisture is one of the biggest challenges in industrial compressed air systems. When air is compressed, water vapor condenses into liquid, which can damage machinery,

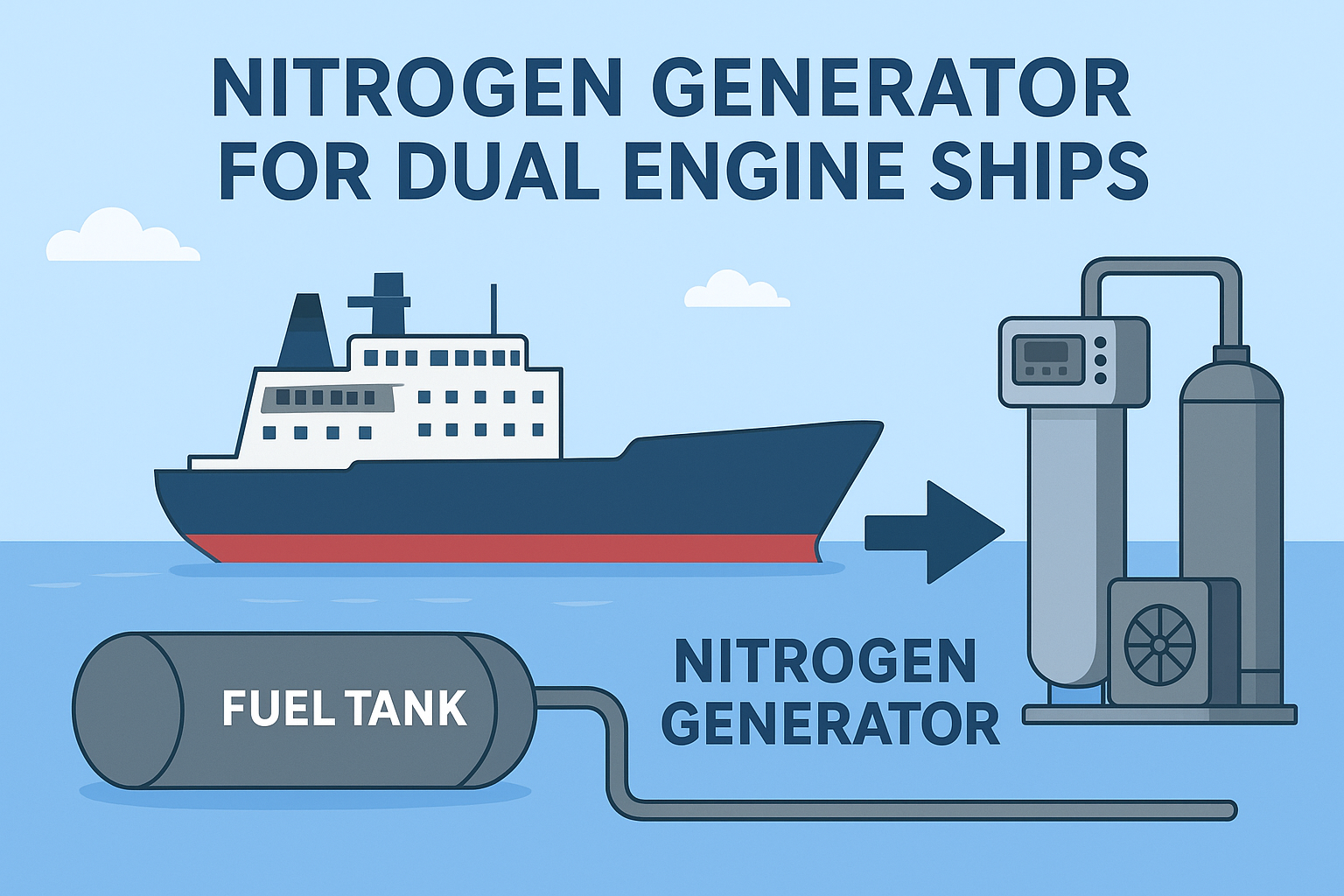

In the marine industry, safety and reliability are top priorities—especially on dual engine ships, where uninterrupted operation is crucial. One technology that has become increasingly

In the food industry, maintaining high-quality standards is crucial for safety, freshness, and shelf life. One important piece of equipment that helps achieve these goals

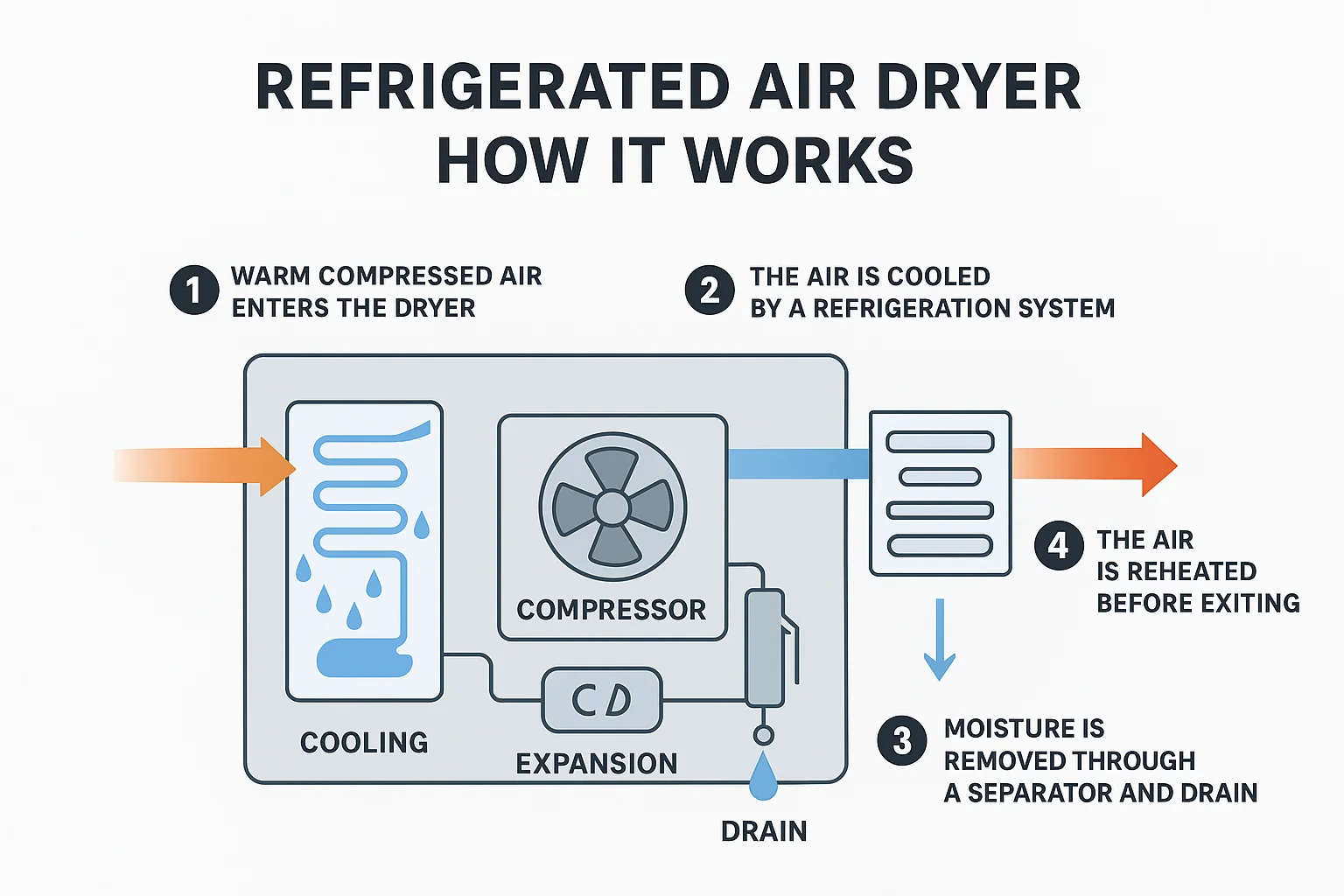

Compressed air is essential in many industries—from manufacturing and automotive to food processing and pharmaceuticals. However, one challenge remains constant: moisture. When warm, humid air

Thermal Regenerative Adsorption Dryer – HH Series Thermal regenerative adsorption dryers, also known as low-heat adsorption dryers, play a critical role in ensuring dry, high-quality

Low Pressure Differential Refrigerated Dryer: What Users Need to Know Low pressure differential refrigerated dryers are essential equipment for ensuring high-quality compressed air in various

Nitrogen is an essential inert gas widely used in industries such as electronics, food packaging, pharmaceuticals, chemical production, and metal processing. For users seeking high-purity

Overview of Shell Tube Refrigerated Air Dryer The shell tube refrigerated air dryer is designed for high-efficiency moisture removal from compressed air systems. Beyond its

Overview of 3-in-1 Plate Heat Exchange Refrigerated Air Dryer The 3-in-1 plate heat exchange refrigerated air dryer integrates pre-cooling, refrigeration, and condensation processes into a