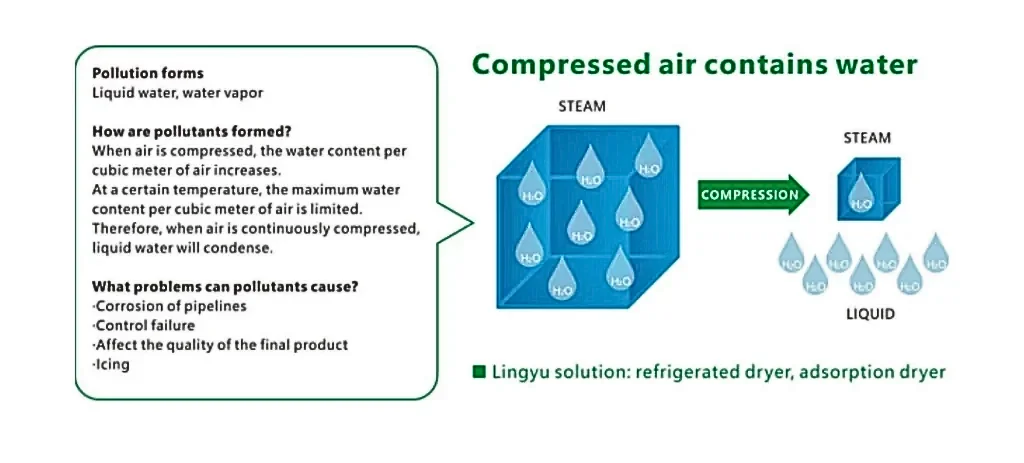

Air that has been compressed by a compressor—making its volume smaller and its pressure higher—is called compressed air. It is the second largest power source after electricity. Untreated compressed air contains large amounts of moisture, oil, dust, and other solid impurities. These impurities enter production processes, causing corrosion and contamination.

Air dryers are especially important for removing these impurities from compressed air. But how to select a compressed air dryer? Follow the five common steps below:

Step 1: Determine the Required Dryness of the Compressed Air Supply

Air dryness (also called moisture content) refers to how much water vapor is in the air. Different industries have different requirements.

And it can be measured using values such as relative humidity, vapor pressure, ppm moisture, or dew point (will be explained in detail in Step 3).

In general, applications with high air-quality requirements—such as precision machining or food processing—need high-performance dryers to reduce the moisture content in compressed air.

Step 2: Determine the Types of Compressed Air Dryers

Quick recap: What is an Air Dryer (Industrial Dryer)?

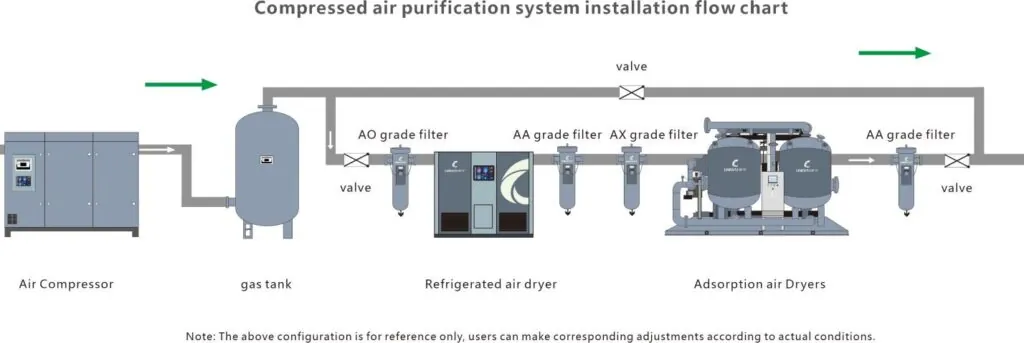

Based on the moisture content and application requirements of compressed air, we can determine the appropriate types of air dryers for compressors.

Currently, there are two main types commonly used in the market:

- Refrigeration Air Dryer

- Desiccant/Adsorption Air Dryer

1. Refrigeration Air Dryer

Refrigeration dryers are one of the most common types of air dryers for compressors due to their high efficiency.

Also, they are mainly suitable for applications that do not require extremely high air dryness levels.

The working principle of refrigeration dryers is the same as that of an air conditioning unit. It uses a compressor, a refrigerant circuit, and a heat exchanger. The refrigerant cools the compressed air, causing the water vapor to condense and be drained away.

This air dryer for air compressor comes in two variants:

These options allow you to choose based on your application and operating preferences.

2. Desiccant Air Dryer

This type of air dryer for compressed air is ideal for applications requiring a higher level of air dryness. It uses moisture-absorbing materials (such as activated alumina) to remove water from the compressed air.

This type of compressed air dryer also comes with different technologies, such as:

Learn more about compressed air dryer selection:

Step 3: Evaluate the Drying Performance of the Compressed Air Dryer

When comparing compressed air dryer manufacturers and their products, the most important task is to evaluate the dryer’s drying performance.

Drying performance is usually related to a key term: dew point. The lower the dew point, the better the drying performance.

- Dew Point: The temperature at which water vapor in the air begins to condense at a given pressure.

- Atmospheric Dew Point: The dew point is measured under standard atmospheric pressure.

- Pressure Dew Point: The dew point is measured at a specific pressure. In compressed air dryer specifications, performance is typically indicated using the pressure dew point.

In addition to pressure dew point, you should also consider parameters such as air flow capacity and working pressure. These values directly affect the dryer’s efficiency and application range.

When evaluating drying performance, refer to the manufacturer’s technical specifications and performance charts.

Step 4: Analyze the Existing Compressed Air System, Consider Practical Application Scenarios

Consider the working environment of the compressed air system, such as temperature, humidity, corrosive gases, and other factors, and choose a dryer that is suitable for that environment.

Before contacting compressed air dryer manufacturers, try to gather the following information:

- A reputable compressor air dryer manufacturer

- The type of compressor you are looking for

- Air temperature at compressor discharge

- The horsepower rating

- Cut out pressure (PSIG)

- Cut in pressure (PSIG)…

Step 5: Consider Energy Consumption and Operating Costs

1. The operating costs for drying the air using compressed air dryers vary depending on the dryer technology used. For example:

- A refrigerant dryer has a low initial cost but moderate running costs.

- An absorption dryer provides more dry air, but it consumes more energy.

2. To a certain extent, for the same air-handling capacity, a lower dew point typically means higher equipment cost, higher operating cost, and higher energy consumption.

When we are in the process of making a decision, we should balance:

- Initial investment vs. long-term savings.

- Energy consumption in kWh per year.

- Maintenance schedules and spare parts availability.

The goal is not always to choose the cheapest dryer, but the one that offers the lowest total cost of ownership over its life cycle.

Contact Lingyu to Find the Right Compressed Air Dryer Solutions

Since 2009, Lingyu has been providing one-stop solutions for all compressed air treatment needs. If you are unsure which model fits your industry, our experts are ready to help. We will analyse your compressed air dryer selection needs, consider your environment, and match you with the most effective solution.

Whether you are looking for a refrigeration model or an adsorption dryer, Lingyu offers a comprehensive portfolio. For a tailored solution, contact our team of experts today.